离心泵前置导叶的优化设计与实验研究

摘要随着国民经济的发展,工程节能问题越来越受到重视。叶片泵作为一种通用机械,在我国各个领域都得到了广泛的应用,同时也消耗了大量的能源,因此其节能意义深远、潜力巨大。针对目前工程中常用的几种离心泵工况调节方式(如节流调节、变速调节)所存在的各种弊端,已有学者提出前置导叶预旋调节理论,在此基础上,本文提出一种新的前置导叶设计思路,并从理论分析和实验研究等方面对离心泵预旋调节的基本规律及调节机理进行了研究。本文作者设计了符合实际工程运用的前导调节机构。借鉴轴流泵孤立叶片水力设计方法设计三组单吸离心泵前置导叶,采用诱导轮设计方法完成双吸离心泵两组不同叶高诱导叶片水力设计。搭建离心泵外特性试验台,通过实...

相关推荐

-

XX中学英语学科质量提升计划书VIP免费

2025-01-09 9

2025-01-09 9 -

VIPKID-美国小学在家上-在线英语学习项目商业计划书VIP免费

2025-01-09 8

2025-01-09 8 -

English TV--英语学习智能视频平台创业商业计划书VIP免费

2025-01-09 11

2025-01-09 11 -

English TV,4--英语学习智能视频平台商业计划书VIP免费

2025-01-09 14

2025-01-09 14 -

260Educotton-让孩子快乐学习英语的平板电脑商业计划书VIP免费

2025-01-09 12

2025-01-09 12 -

XX英语学校创业策划书VIP免费

2025-01-09 12

2025-01-09 12 -

Ustudy-K12英语在线学习产品商业计划书VIP免费

2025-01-09 14

2025-01-09 14 -

Strawberry English School (SES)英语培训学校计划书VIP免费

2025-01-09 18

2025-01-09 18 -

《天中英语智能电子公司创业商业计划书》VIP免费

2025-01-09 14

2025-01-09 14 -

XXXX少儿英语培训学校创业计划书VIP免费

2025-01-09 21

2025-01-09 21

相关内容

-

XX英语学校创业策划书

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:WPS

价格:10 积分

-

Ustudy-K12英语在线学习产品商业计划书

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:PPTX

价格:10 积分

-

Strawberry English School (SES)英语培训学校计划书

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:DOC

价格:10 积分

-

《天中英语智能电子公司创业商业计划书》

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:DOC

价格:10 积分

-

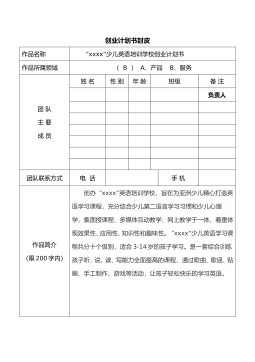

XXXX少儿英语培训学校创业计划书

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:DOC

价格:10 积分