含纳米微粒的低温保护剂热物性的DSC研究

摘要玻璃化保存可以避免生物体在冻结和复温过程中的损伤,实现生物体长期稳定保存,是目前最理想的低温保存方法之一。但由于受降温速率和低温保护剂溶液浓度的限制,相对复杂和较大的组织和器官很难实现玻璃化保存。通过改变物质外部的温度环境而提高降温速率的方法已经做了大量研究,并取得了显著成果,而针对改变物质内部传热传质特性,以提高降温速率的方法研究还鲜见报道。常温下纳米微粒可以显著增强溶液的传热效果,将纳米微粒应用到低温保存领域,分析纳米低温保护剂溶液在冻结过程中热物性参数的变化及纳米微粒对玻璃化趋势影响的研究是非常必要的。本课题通过配制稳定的纳米悬浮液,利用差示扫描量热仪(DSC)判定羟基磷灰石(HA)...

相关推荐

-

XX中学英语学科质量提升计划书VIP免费

2025-01-09 8

2025-01-09 8 -

VIPKID-美国小学在家上-在线英语学习项目商业计划书VIP免费

2025-01-09 8

2025-01-09 8 -

English TV--英语学习智能视频平台创业商业计划书VIP免费

2025-01-09 11

2025-01-09 11 -

English TV,4--英语学习智能视频平台商业计划书VIP免费

2025-01-09 14

2025-01-09 14 -

260Educotton-让孩子快乐学习英语的平板电脑商业计划书VIP免费

2025-01-09 12

2025-01-09 12 -

XX英语学校创业策划书VIP免费

2025-01-09 11

2025-01-09 11 -

Ustudy-K12英语在线学习产品商业计划书VIP免费

2025-01-09 12

2025-01-09 12 -

Strawberry English School (SES)英语培训学校计划书VIP免费

2025-01-09 16

2025-01-09 16 -

《天中英语智能电子公司创业商业计划书》VIP免费

2025-01-09 13

2025-01-09 13 -

XXXX少儿英语培训学校创业计划书VIP免费

2025-01-09 21

2025-01-09 21

相关内容

-

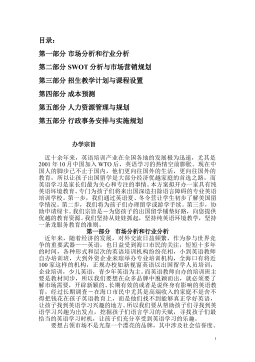

XX英语学校创业策划书

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:WPS

价格:10 积分

-

Ustudy-K12英语在线学习产品商业计划书

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:PPTX

价格:10 积分

-

Strawberry English School (SES)英语培训学校计划书

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:DOC

价格:10 积分

-

《天中英语智能电子公司创业商业计划书》

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:DOC

价格:10 积分

-

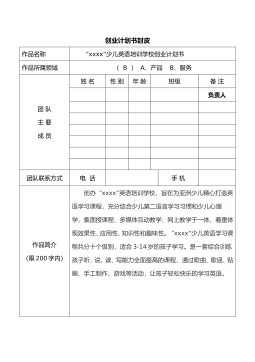

XXXX少儿英语培训学校创业计划书

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:DOC

价格:10 积分