热等离子体环境下溶液液滴蒸发机理研究

摘要溶液注入热等离子体喷涂(solutionprecursorplasmaspray,SPPS)用以制备纳米涂层,是热喷涂技术中重要的工艺技术和方法之一。在溶液注入热等离子体喷涂过程中,溶有涂层材料的前体盐溶液,经过加压雾化,形成喷雾液滴,以一定的速度射入热等离子体环境。喷雾液滴在热等离子体中加速运动,吸收热量,液滴温度逐渐升高。随着溶剂的蒸发,液滴溶质浓度增大,达到临界过饱和浓度后,溶质析出,形成中空壳状或实心固体等不同形态的颗粒。液滴的运动和加热历程,对涂层性能有至关重要的影响。本文首先建立了溶液液滴在热等离子体内的运动模型,模拟液滴在热等离子体中的运动和传热,综合考虑了液滴、热等离子体气...

相关推荐

-

XX中学英语学科质量提升计划书VIP免费

2025-01-09 9

2025-01-09 9 -

VIPKID-美国小学在家上-在线英语学习项目商业计划书VIP免费

2025-01-09 8

2025-01-09 8 -

English TV--英语学习智能视频平台创业商业计划书VIP免费

2025-01-09 11

2025-01-09 11 -

English TV,4--英语学习智能视频平台商业计划书VIP免费

2025-01-09 14

2025-01-09 14 -

260Educotton-让孩子快乐学习英语的平板电脑商业计划书VIP免费

2025-01-09 12

2025-01-09 12 -

XX英语学校创业策划书VIP免费

2025-01-09 12

2025-01-09 12 -

Ustudy-K12英语在线学习产品商业计划书VIP免费

2025-01-09 13

2025-01-09 13 -

Strawberry English School (SES)英语培训学校计划书VIP免费

2025-01-09 18

2025-01-09 18 -

《天中英语智能电子公司创业商业计划书》VIP免费

2025-01-09 14

2025-01-09 14 -

XXXX少儿英语培训学校创业计划书VIP免费

2025-01-09 21

2025-01-09 21

作者详情

相关内容

-

XX英语学校创业策划书

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:WPS

价格:10 积分

-

Ustudy-K12英语在线学习产品商业计划书

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:PPTX

价格:10 积分

-

Strawberry English School (SES)英语培训学校计划书

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:DOC

价格:10 积分

-

《天中英语智能电子公司创业商业计划书》

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:DOC

价格:10 积分

-

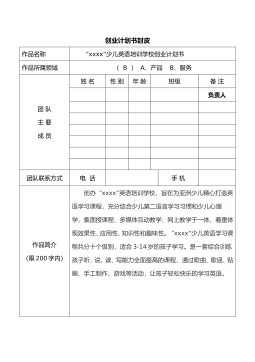

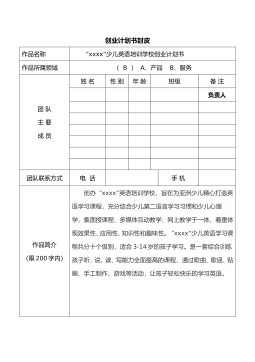

XXXX少儿英语培训学校创业计划书

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:DOC

价格:10 积分