ADA螯合纤维素的合成与吸附性能研究

第一章绪论ADA螯合纤维素的合成与吸附性能研究摘要本文主要以去除水体中的重金属污染物为主要研究目的,将ADA(N-(氨基甲酰甲基)亚氨基二乙酸)接枝于纤维素分子链上,合成了一种新型环境功能材料,用于治理水体中重金属污染,对其吸附过程的热力学、动力学及吸附稳定常数等诸多特征进行研究,探讨其相应的吸附机理。本文通过将ADA(N-(氨基甲酰甲基)亚氨基二乙酸)基团接枝到纤维素上,制备了具有氨基、羧基等配位体的DA螯合纤维素。考察了反应温度、反应时间、质量比、碱浓度等因素对接枝情况的影响,采用四因素三水平正交表及单因素影响实验来进行研究,得到其最优的合成条件:反应温度343K,ADA与纤维素的质量比1...

相关推荐

-

南京监狱罪犯危机干预系统评估报告VIP免费

2024-10-15 6

2024-10-15 6 -

中国政府采购制度研究VIP免费

2024-10-15 9

2024-10-15 9 -

政府采购运行效率要素分析VIP免费

2024-10-15 7

2024-10-15 7 -

政府采购效率浅析VIP免费

2024-10-15 7

2024-10-15 7 -

政府采购的效率从何而来VIP免费

2024-10-15 7

2024-10-15 7 -

正确的政府采购效率观VIP免费

2024-10-15 6

2024-10-15 6 -

影响政府采购效率的因素分析及对策VIP免费

2024-10-15 7

2024-10-15 7 -

影响政府采购效率的几个因素及解决措施VIP免费

2024-10-15 8

2024-10-15 8 -

学好政府采购法_提高中央国家机关单位政府采购工作效率VIP免费

2024-10-15 13

2024-10-15 13 -

完善政府采购法规提高政府采购效率VIP免费

2024-10-15 18

2024-10-15 18

相关内容

-

创青春-公益创业赛项目书

分类:行业资料

时间:2025-01-09

标签:无

格式:DOCX

价格:10 积分

-

茶文化-剪纸公益项目计划书

分类:行业资料

时间:2025-01-09

标签:无

格式:DOC

价格:10 积分

-

xxx公益创业大赛策划书

分类:行业资料

时间:2025-01-09

标签:无

格式:DOC

价格:10 积分

-

“筑爱助残-共享阳光”公益项目说明书

分类:行业资料

时间:2025-01-09

标签:无

格式:DOC

价格:10 积分

-

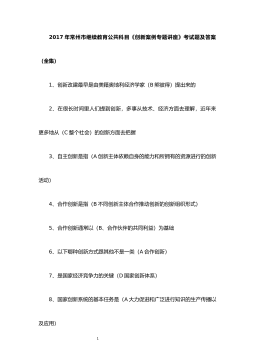

2017 常州市继续教育公共《创新案例专题讲座》考题

分类:行业资料

时间:2025-03-06

标签:2017 常州 继续教育 公共 创新案例专题讲座

格式:DOCX

价格:5 积分