离散颗粒相浓度和粒度的超声非接触式测量研究

摘要在工业生产中,涉及颗粒两相流中颗粒粒径及其分布的测量如气力输送、水煤浆的管道输送、化工和制药业中各种悬浮液和乳剂制备中的颗粒在线测量,正日益引起人们的重视。这类测量问题的一个显著特点是颗粒的浓度高而粒径较小,需要进行在线测量,光散射法因为透射能力弱不宜采用。而其它一些方法,如电容法则不能测量颗粒的粒径。超声法在这类高浓度颗粒两相流的测量中具有明显的优点,体现在非侵入、快速、无需对样品进行稀释等,适合工业现场测量。超声衰减谱法正发展成为一种应用范围比较广的粒度表征技术。本文作者基于此方法搭建了一套超声在线非接触式液固两相高浓度纳米颗粒悬浮液的粒度分布和浓度测量系统,通过分析在线非接触式测量系...

相关推荐

-

【拔高测试】沪教版数学五年级下册期末总复习(含答案)VIP免费

2024-11-19 20

2024-11-19 20 -

【基础卷】小学数学五年级下册期末小升初试卷四(沪教版,含答案)VIP免费

2024-11-19 10

2024-11-19 10 -

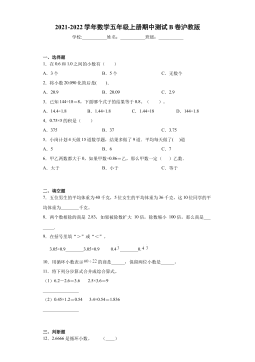

期中测试B卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 12

2024-11-19 12 -

期中测试B卷(试题)- 2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 18

2024-11-19 18 -

期中测试A卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 19

2024-11-19 19 -

期中测试A卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 26

2024-11-19 26 -

期中测B试卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 25

2024-11-19 25 -

期中测A试卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 33

2024-11-19 33 -

【七大类型简便计算狂刷题】四下数学+答案

2025-03-18 16

2025-03-18 16 -

【课内金句仿写每日一练】四下语文

2025-03-18 44

2025-03-18 44

作者详情

相关内容

-

期中测试A卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

期中测B试卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

期中测A试卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

【七大类型简便计算狂刷题】四下数学+答案

分类:中小学教育资料

时间:2025-03-18

标签:数学计算;校内数学

格式:PDF

价格:1 积分

-

【课内金句仿写每日一练】四下语文

分类:中小学教育资料

时间:2025-03-18

标签:无

格式:PDF

价格:1 积分