退火炉自动控制系统的研究与实现

VIP免费

- I -

东北大学硕士学位论文 摘要

退火炉自动控制系统的研究与实现

摘 要

本文介绍了由全氢罩式炉机组组成的全氢罩式退火炉控制系统。该系统使用 的是

PLC控制系统,该系统是PLC控制系统的一个大系统,无论是从控制的点数和 需要采集

的数据类型方面,还是从整个系统架构通信方面,突出体现了PLC控制 功能的强大。该

项目的PLC控制系统,具有易于管理控制,自动化程度高的特点。

退火工艺在金属的热处理中扮演很重要的角色,其主要起软化金属硬度、去 除金属

的内部作用力和细分金属内部组织的作用。退火炉作为钢带生产成型的主 要设备之一,

具有关键位置,很大程度上影响了产品的产量、质量和成本。本文讨论了如何实现退火

工艺的实现过程,该退火具有自动控制的特点以及监控画面 实时监控的特点,使用了

Siemens S7系列的PLC以及WinCC图形组态软件来实现。 该退火炉的温度控制系统在使

用了传统的PID控制算法,结合了在烧嘴方面的控 制技术,即脉冲循环燃烧方式。通过

这两者的结合,很明显的使得温控精度的提 高。监控系统是由WinCC组态软件设计而成

的,是一个冗余的结构,上位机与下位机PLC之间采用的工业以太网进行通信;控制器

PLC与各分布式I/O站通过 PROFIBUS构成网络,实时对系统设备进行控制。在监控系统

上,显示了炉子的工 艺过程的监控状态,实时数据等。为了实现现场的真实情况,共设

计了十几个监 控画面,管控现场各方面的信息。系统的下位机通过结构化的编程实现退

火炉的 各个控制任务。

本文详细介绍了整个退火炉系统的结构,组态情况,以及监控系统的设计等 方面,

重点进行了控制算法的研究。目前很多厂商在温控方面使用了烧嘴连续燃 烧的控制方式

效果有限。本文采用的脉冲循环燃烧的温控方法是非连续的控制 方法,烧嘴间断循环工

作,提高了退火工艺的质量。并且由于烧嘴是间断的交替 燃烧,所以对延长设备的工作

寿命有益处。本文对全氢罩式退火炉项目控制系统 进行了阐述,采用西门子的Step7编程

软件开发设计了烧嘴循环燃烧控制程序, 并且运用上位机WinCC监控软件设计了监控系

统。运行结果说明了该系统控制性 能优越,效果良好。

关键词:退火炉;PLC;WinCC;脉冲燃烧

- II -

东北大学硕士学位论文 Abstract

Research and Implementation on Automatic Control System of The

Annealing Furnace

Abstract

T h i s ar t i c l e descr i bes a fu l l hydrogen bell-type anne al i n g fur nace co n t r o l syst e m

composed by hydrogen bell-type furnace unit. The system uses PLC control system, which

is a complex system of PLC control system, either from the control points or the type of

data t o b e co l le ct e d fro m and t h e en t i r e sys t e m arch i te ctur e co m m u n i cat i o n s , represen t a

powerful PLC control functions. The PLC control system, easy to control, a high degree of

automation features.

A n neal ing proc es s p lays a very i m p o rtan t r o l e i n t h e he at t reat men t o f m e tal s ,

m a i nly fro m s o f ten ing m e tal har d nes s , rem o v i n g t h e i n ternal f orce o f th e m e tal an d

subdividing the internal organization of the metal. Annealing furnace as one of the major

equipment as steel strip production, has a key position and a good extent affect the yield,

quality and cost of the product. This article discusses how to implement the process of the

r eal izat i o n o f t h e an neal i n g proc es s . T h e an neal i n g has t h e char act eri s t i c s of t h e

automatic control and monitoring of the characteristics of the real-time monitoring of the

screen, using the Siemens S7 ser ies PLC and Wi n CC graphics configurat ion soft ware.

T h e anne al ing f urnace t e mperat ure cont r o l sys t e m u s e s t h e t rad i t i o n a l PID co n t r o l

algori thm, and a combinati o n of t he burner control t echnology, pulse cycle combust ion

m o d e . Thro ugh t h e co m b i nat ion o f b o t h , o b v i o u sly i m pro v e t h e a c curacy o f the

temperature control. Monitoring system is designed and made by the WinCC configuration

software, it is a redundant structure for communication between the host computer and the

PLC from Industrial Ethernet; the controller PLC with distributed I/O station via PROFIBUS

co n s t i t u t e t h e net w o rk, real-t i m e co n t r o l sys t e m eq u i p men t . T h e m o n itori n g sys t e m ,

displays the furnace process monitoring state and the real-time data. In order to realize the

true situation of the scene, monitor screens were designed to control all aspects of the site

i n f orm a t i o n . PLC a ch i eves t h e anne alin g fur nace co n t r o l tas k s thro ugh s t ruct u red

programming.

Th i s paper descr ibes th e s t r uct ure o f the enti r e anne al i n g f urnace syst e m ,

co n f igurat i o n , an d m o nit o r i n g sys t e m design , focu s i n g o n t h e s t udy o f t h e co n t r o l

algori t h m . M any m a n u fact u rer s u s e t h e co n t i n u ous co m b u s t i o n co n t r o l way, however t h e

effect is l im it ed. The t e mperat ur e co nt ro l met ho d of a n on-co nti nu ou s co ntr ol m et hod

is used in this paper. The pulse cycle combustion burner intermittent cycle work, improve

the quality of the annealing process. And burner intermittent alternating burning,

extend the life of equipment. In this paper full hydrogen bell-type annealing furnace project

control system is described, using Siemens Step7 programming software development design

t h e b u r ner cycle co m b u s tio n co n t r o l proc ed ures , an d u s e of th e h o s t co m p u ter Wi n C C

monitoring software to design a monitoring system. The run results demonstrate the system

- III -

东北大学硕士学位论文 Abstract

control performance has a good effect.

Key words: The annealing furnace; PLC; WinCC; Pulse burning

- IV -

东北大学硕士学位论文 目录

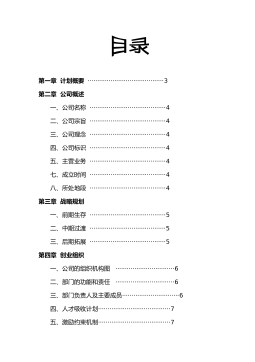

目 录

摘 要...........................................................................................................................................I

Abstract......................................................................................................................................II

第1章 绪 论...............................................................................................................................1

1.1 选题背景及其研究意义..............................................................................................1

1.2 简述该领域目前的国内外先进水平..........................................................................1

1.3 主要研究内容..............................................................................................................2

第2章 退火工艺程序描述.........................................................................................................4

2.1退火炉简介....................................................................................................................4

2.1.1 退火炉概述.........................................................................................................4

2.1.2 全氢罩式退火炉的热点.....................................................................................4

2.2 退火工艺流程..............................................................................................................5

第3章 系统主要配置...............................................................................................................12

3.1 上位监控及 PLC 控制系统........................................................................................13

3.3 传动控制.....................................................................................................................21

第4章 控制系统硬件设计与实现...........................................................................................22

4.1 PLC的基本工作原理..................................................................................................22

4.2 PLC 程序设计语言.....................................................................................................23

4.3基于Step7的PLC程序设计..........................................................................................25

4.4 温度控制的分析与设计............................................................................................28

4.4.1 脉冲控制算法...................................................................................................28

4.4.2 控制算法的实施...............................................................................................30

第5章 上位机监控系统的设计...............................................................................................40

5.1 WinCC 监控软件的分析............................................................................................40

5.1.1 WinCC的主要功能..........................................................................................40

5.1.2 WinCC 软件的组成概述.................................................................................42

5.2 上位机监控软件的设计.............................................................................................44

5.2.1 WinCC 创建项目的过程.................................................................................44

5.2.2 主要监控界面介绍...........................................................................................51

5.3 运行结论.....................................................................................................................62

第6章 结论与展望...................................................................................................................66

6.1 结论.............................................................................................................................66

6.2 展望.............................................................................................................................67

参考文献..................................................................................................................................68

在读期间公开发表的论文和承担科研项目及取得成果......................................................73

致 谢.........................................................................................................................................74

- 1 -

东北大学硕士学位论文 第1章 绪论

第1章 绪 论

1.1 选题背景及其研究意义

随着我国工业的发展,在建筑、汽车、家电等行业冷轧钢板的需求越来越大,在我

们日常生活中日益发挥着越来越重要的作用。带钢是很多产品重要的材料,它的质量非

常受关注。退火是金属热处理中的重要工序,是将偏离平衡状态的金 属加热到临界温度

以上,保持一定时间,然后缓慢冷却,以得到接近于平衡状态 组织的过程[1,2]。通过退

火可以达到细化组织、降低硬度、改善切削加工性能、消 除内应力等目的[3]。所以本人

研究的带钢的控制系统在提高带钢质量和环境保护方 面都明显的作用。首先,能提高企

业生产效益。为了支持企业的业务需求,明确 企业的利润,以及创造更多的利润,提高

生产效率是一个关键措施,尽可能地在 单位时间内输出合格的产品,在生产过程中体现

投资和利润的权衡关系,在控制方法上优化改进过程。其次,能够减少能源的消耗。工

艺过程会产生废气,废气 里面带有很多的热量,对废气的余热回收能节能。此外,在炉

体结构的改善也在 节能方面有所效果。但是这些成本都很高,节能效果很微弱。第三,

能提高产品 产量和质量。炉内的温度控制是重点,炉子内部的温度曲线对产品的质量有

影响, 温度与设定值的偏差过高和过低都对产品有很大的影响。通过对温度曲线的控制

可以降低整个生产过程的时间,提高成品率。尤其重要的是,能够改善生态环境。 工业

大气的污染一直是社会关注的重点,燃烧过程中尾气含有大量的污染气体, 对温度造成

较大的影响。如果在控制过程中合理的安排了燃烧气体与空气中氧气 的比例,合理的比

例可以是燃料完全燃烧,提高燃气的可用率,降低有毒气体的 排放。在节能环保越来越

重视的今天,通过在控制过程的改进来实现节能环保具 有长远的意义。

1.2 简述该领域目前的国内外先进水平

在发达国家,早在二十世纪的六七十年代就开始进行退火炉的使用和研究,因 为金

属的热处理在工业方面运用得非常的广泛。日本的一些厂商,在燃气和空气 的燃烧比方

面,钢带的炉温曲线方面,产品出炉的温度预测方面,都有重大的进 展;美国一些公司

在工艺过程的物料跟踪,生产模型的建模,生产调度方面也 有了不错的发展;欧洲的一

些公司,在炉温曲线的仿真,产品的建模方面有较好

- 2 -

东北大学硕士学位论文 第1章 绪论

的发展[4]。近年来,退火炉的控制进入到了自动控制的第三个层次,实现了整个生 产线

物料跟踪的高度自动化控制系统。

我国的工业起步较晚,研究工作人员的理论和实际的水平都有限,所以尽管改 革开

放后理论研究方面有了很大的提高,但是与国外的技术差别仍然很大。由于 设备落后等

原因,在一些中小型企业中,控制系统通常采用常规的温度调节仪表 或者通过操作者人

工操作来控制退火炉炉温[5,6]。我国的工业发展水平的限制,自 动化程度较低,导致了

产品的合格率很低,也产生了很多环境问题,在资源的环 境的保护方面有很大改经的空

间。

国内,有些企业从20世纪80年代起,开始对退火炉控制进行广泛的研究,使退 火炉

计算机控制在逐步转入实用化阶段,主要研究现状如下所示。

1.采用计算机控制设备 在传统的工业控制中,模拟仪表以及自动化程度低的继电器

等使用广泛,控制

效果不进入人意。随着技术人员理论研究的深入以及国外技术的传入,一些高级

的控制算法和控制理念得到了传播,如DCS控制,算法方面有模糊控制,最优控 制等的

发展[7,8]。这些设备通过软件控制和联网通信,使用方便。极大的提高了生 产效率以及

改善了劳动条件,极大的降低生产的成本。

2.采用现代控制理论的方法 随着控制理论的深入研究,现代控制理论得到了很好的

发展,很多控制系统逐

渐开始采用现代控制理论的一些控制方法,如自适应控制,模糊控制,最优控制,

自整定PID参数控制,神经网络控制等,得到了较好的发展,已逐步在工业中得到 应用

[9,10]。

1.3 主要研究内容

为了满足退火炉的工艺需求,温度控制是退火炉退火产品成功的关键因素。需 要保

证内罩里面温度均匀,在整个工艺流程的过程中,要实现快速升温,平稳保 温。本控制

系统有很多的部分构成,在退火炉控制机组方面,包含了内罩、加热 罩、液压站以及

PLC自动化控制系统等。控制系统庞大,监测点多,干扰因素多。 由于现场环境复杂,

加热过程又具有惯性的特点,各部件之间存在着非线性等控 制特点,所以控制系统的实

施是一件需要好好设计的工作。

自动化控制部分,主要由西门子WinCC6.1冗余服务器、操作终端,西门子S7-300

PLC,西门子ET 200M I/O站,冗余工业交换以太网络等组成。 控制系统需要实现的是,

让退火工艺按着设定的流程运行。产品的工艺流程是按照生产过程的一系列步骤来的。

带钢的生产过程上的工艺流程是:液压锁紧内罩→冷态密封检查→冲氢气保护→点火升

温→保温→热态密封检查→风冷却→水 冷却→排空氢气等。

在上位机上面,本系统采用与西门子的PLC相配套的西门子WinCC组态软件实 现上

位机的监控功能,采用WinCC 6.1冗余服务器和客户端结构。

上位监控系统主要具有如下功能:

1.采集、记录、显示、PLC工作状态,显示系统工作流程。

2.设定和修正PLC退火工艺。

3.记录气体流量和用量累计(PLC计算)。

摘要:

展开>>

收起<<

-I-东北大学硕士学位论文摘要退火炉自动控制系统的研究与实现摘要本文介绍了由全氢罩式炉机组组成的全氢罩式退火炉控制系统。该系统使用的是PLC控制系统,该系统是PLC控制系统的一个大系统,无论是从控制的点数和需要采集的数据类型方面,还是从整个系统架构通信方面,突出体现了PLC控制功能的强大。该项目的PLC控制系统,具有易于管理控制,自动化程度高的特点。退火工艺在金属的热处理中扮演很重要的角色,其主要起软化金属硬度、去除金属的内部作用力和细分金属内部组织的作用。退火炉作为钢带生产成型的主要设备之一,具有关键位置,很大程度上影响了产品的产量、质量和成本。本文讨论了如何实现退火工艺的实现过程,该退火具...

相关推荐

-

新能源项目融资计划VIP免费

2024-12-31 12

2024-12-31 12 -

新能源汽车运营服务公司商业计划书VIP免费

2024-12-31 7

2024-12-31 7 -

上海xxx新能源股份有限公司商业计划书VIP免费

2024-12-31 47

2024-12-31 47 -

绿特新能源商业计划书VIP免费

2024-12-31 9

2024-12-31 9 -

关于新能源充电项目创业计划VIP免费

2024-12-31 13

2024-12-31 13 -

太阳能充电器创业计划书模板VIP免费

2025-01-09 5

2025-01-09 5 -

中国新能源及节能环保材料项目商业计划书VIP免费

2025-01-09 4

2025-01-09 4 -

中国(陕西)xxxx新能源股份有限公司VIP免费

2025-01-09 4

2025-01-09 4 -

阳光新能源公司创业计划书VIP免费

2025-01-09 4

2025-01-09 4 -

新型纯电动安全汽车项目商业计划书VIP免费

2025-01-09 5

2025-01-09 5

作者:朱铭铭

分类:高等教育资料

价格:15积分

属性:51 页

大小:1.65MB

格式:DOC

时间:2024-09-30