基于湿膜的露点式蒸发冷却系统研究

VIP免费

摘 要

随着人类环境保护意识、对环保要求标准和对居住环境舒适度要求的不断提高,

建筑制冷技术的革新再次成为各科研领域的热门话题。而在减少或不对自然环境

造成破坏的前提下,将建筑与自然的完美结合将是各行业科研工作者所追求的终

极目标。伴随此理念诞生的新技术和对原有技术的革新层出不穷。蒸发冷却技术就

是其中之一。它即是古老的又是新兴的,它的基础理论很早就被人类发现并利用,

但真正结合现代科学技术的研究和运用的时间并不长,还有很多与热质交换相关

的理论问题需要我们继续深入的研究探讨。同时露点式蒸发冷却的制冷设备还存

在很多不足,这方面的课题研究工作在世界范围内一直都在进行。在我国,对露点

式蒸发冷却的研究还处于初期阶段。

本课题主要研究露点式蒸发冷却系统。论文作者设计研发了一套露点式蒸发冷

却装置。通过实验测试不同进口温度、湿度和不同组成形式下的热湿交换效果,研

究进口参数对露点式蒸发冷却系统性能的影响,比较不同通道组合形式的热质交

换。

首先,本文阐述了实验装置的设计思路及具体参数。实验台通过不同的布水方

式可以实现四种不同形式的实验,只要在不同的通道布好测点就可以完成不同蒸

发冷却方式的对比试验。论文作者针对目前市场上较常见的材料进行了物性的对

比分析,并选取一种作为本文实验台所用的填料材料。总结了影响热质传递程度的

9大要素包括:水膜层的温度、入口空气的温度、入口空气的湿度等。对于其中的

核心问题之一的水膜材料来说最关键的为比表面积、润湿保水性能和热力性能。

其次,本文分析了不同布水运行方式、不同条件参数下各种工况运行的特点和

温度场分布、湿度场分布等。然后阐述了两种用于评价蒸发冷却器性能的指标,并

利用这两种指标比较了实验中两种布水运行方式的效率和多级模拟中几种系统形

式的效率。实验数据表明,全系统布水方式比半系统布水方式的冷却效果要好。而

在相同的布水方式和运行参数的情况下,低湿度的时候干通道进出口温度差会比

高湿度时高,但效率反而会比高湿度的时候低。

再次,本文对露点式蒸发冷却进行了模拟研究。经过模型搭建及参数调整,将

模拟误差控制在 10%以内。除了传热过程的模拟,本文还进行了传质过程的模拟,

即水的蒸发过程模拟。根据模拟所得结果,详细描述了三种模型的模拟结果,从压

力场、流动场、温度场、湿度场等不同方面分别进行了对比分析和说明,同时依据

模拟结果分析了流动场、温度场、湿度场之间的耦合关系,结论表明微尺寸蒸发冷

却器半流量多级冷却的效果是最好的。在入口空气参数、运行速度相同的情况下,

冷却到同样的温度,微尺寸模型所需要的级数更少,效率更高。

最后,通过用上海地区实际参数的计算结果提出了将露点蒸发冷却系统与除湿

系统结合使用以达到理想结果的假设。并依据实验和模拟数据,针对本实验台提出

了优化方案和改进方向。

关键词:蒸发冷却 实验研究 数值模拟 露点式循环 干湿通道

ABSTRACT

With the improvement of environmental protection consciousness, the environmental

protection standards and the requirement of comfort living environment, air-cooling

technology’s innovation has become a hot topic in the field of scientific research once

again. Under the premise of reducing or on damage for the natural environment, the

ultimate goal of scientific researchers is perfect combination of architecture and nature.

With this concept, new technology and innovation of the original technology is emerging

in endlessly. Evaporative cooling technology is one of them. It is antiquity and newly-

developing, its basic theory was discovered and used long before, but combined with

modern science and technology research is not long. There are a lot of heat and mass

transfer and related theory problems we need to further study. Also dew point evaporative

cooling’s equipment also has many shortcomings, the research work have been no stop in

the world. In the domestic, the study of dew point evaporative cooling is still in its early

stage.

This paper is about the dew point evaporative cooling technology. A set of dew point

evaporative cooling unit has been developed independently. Through testing the data

under different inlet temperature, humidity and the heat transfer effect to study different

inlet parameters’ influent on this unit cooling effect, which can compare the heat transfer

effect of different channel form.

Firstly, this paper introduces the design of experiment device and specific parameters.

By different ways of cloth water, it can realize the four different forms of experiment. In

addition, before building test bench, comparison study of the packing materials used for

the test bench has been made, common materials in present market are analyzed in

comparison of physical properties, and a packing material has been selected and used on

the test bench. The nine main factors that affect the degree of thermal and mass transfer

have been summarized, which include the temperature of the water film layer, the inlet

air temperature, the inlet air humidity and so on. For one of the core issues water film

materials, the main factors are the specific surface area, water-retaining property, thermal

performance.

Secondly, different way of water distribution parameters under different conditions,

operation characteristics and temperature distribution under various working conditions,

etc. have been analyzed in this paper. Then two indexes for evaluating the performance

of evaporative cooler have been introduced, Comparison of the two kinds of cloth water

operation efficiency and the efficiency of multi-stage simulation system types using these

two indexes has been made. Experimental data show that the whole system water

distribution mode is better than half system water distribution mode of cooling effect.

And in the same way of the water distribution and under the same condition of operation

parameters, the dry channel import and export temperature difference is higher in low

humidity, but the efficiency is lower than the high humidity.

Thirdly, the simulation research of the dew point evaporative cooling has been made

in this paper. Through the model building and parameter adjustment, the simulation error

be controlled less than 10%. In addition to the heat transfer process of simulation, this

article also has carried on the simulation of mass transfer, the water evaporation process

simulation. According to the simulation results, the simulation results of the three models,

the pressure field, flow field, temperature field and humidity field has been described in

detail, different aspects has carried on the comparative analysis and illustrate respectively.

At the same time, the results of simulation analysis of the flow field, temperature field

and humidity field coupling relationship show that the micro size half speed multi-stage

evaporation cooler cooling effect is the best. Under the same condition of speed, number

of cooling stages and inlet air parameters, the micro size required less stages, efficiency

is higher, when cooling to the same temperature.

Finally, according the calculation results for Shanghai area actual parameters, the

combination of dew point evaporative cooling and dehumidification system is put

forward to achieve the ideal result. And on the basis of the experimental and simulation

data, this paper put forward the optimization scheme for this test bench and the

improvement direction.

Key Words: Evaporative Cooling, Experimental Study, Numerical

Simulation, Dew Point Cycle, Dry-Wet Channel

目 录

中文摘要

ABSTRACT

第一章 绪论 ................................................................................................................. 1

§1.1 课题研究背景 ............................................................................................... 1

§1.1.1 蒸发冷却技术的发展历史 ............................................................... 1

§1.1.2 露点式蒸发冷却技术的提出及研究 ............................................... 1

§1.1.3 蒸发冷却技术在空气调节领域的应用 ........................................... 2

§1.2 国内外研究现状 .......................................................................................... 3

§1.2.1 露点式蒸发冷却结构形式的研究 ................................................... 3

§1.2.2 露点式蒸发冷却膜材料的研究 ....................................................... 4

§1.3 本文的内容和意义 ...................................................................................... 6

第二章 露点式蒸发冷却的理论 ................................................................................. 7

§2.1 直接式蒸发冷却的原理 .............................................................................. 7

§2.2 间接式蒸发冷却的原理 .............................................................................. 8

§2.3 露点式蒸发冷却的原理 ............................................................................ 10

§2.4 热质传递的耦合作用 ................................................................................ 12

§2.5 影响空气与水之间热质交换的主要因素 ................................................ 12

§2.6 水膜材料的性能对换热过程的影响 ........................................................ 13

§2.7 本章小结 .................................................................................................... 14

第三章 露点式蒸发冷却实验系统 ........................................................................... 15

§3.1 实验概述 .................................................................................................... 15

§3.2 实验辅助系统 ............................................................................................ 16

§3.3 露点式蒸发冷却器实验装置 .................................................................... 16

§3.3.1 设计思路 ......................................................................................... 16

§3.3.2 实验装置主体结构 ......................................................................... 17

§3.3.3 实验台运行流程及组合方式 ......................................................... 20

§3.3.3.1 实验台运行流程 .................................................................. 20

§3.3.3.2 组合方式 .............................................................................. 20

§3.3.4 形成水膜的填料选取 ..................................................................... 21

§3.4 实验台数据测量与采集 ............................................................................ 22

§3.4.1 温度的测量 ..................................................................................... 22

§3.4.2 湿度的测量 ..................................................................................... 23

§3.4.3 速度的测量 ..................................................................................... 24

§3.4.4 数据采集 ......................................................................................... 24

§3.5 实验步骤与内容 ........................................................................................ 25

§3.5.1 实验步骤 ......................................................................................... 25

§3.5.2 实验工况 ......................................................................................... 26

§3.6 本章小结 .................................................................................................... 27

第四章 露点式蒸发冷却系统的性能模拟 ............................................................... 28

§4.1 CFD 数值模拟方法介绍 ........................................................................... 28

§4.1.1 CFD 简介 ......................................................................................... 28

§4.1.2 常用的 CFD 软件简介 .................................................................. 28

§4 .1.3 模拟和计算软件及步骤 ................................................................. 28

§4.1.3.1 Fluent14.5 新特点 ................................................................. 29

§4.1.3.2 CFD 数值模拟步骤 .............................................................. 29

§4.2 数值方法 .................................................................................................... 32

§4.2 建立模型划分网格 .................................................................................... 33

§4.2.1 物理模型 ......................................................................................... 33

§4.2.2 网格划分 ......................................................................................... 34

§4.3 物理边界条件和初始条件 ........................................................................ 36

§4.4 数值模拟结果 ............................................................................................ 37

§4.4.1 整体模型研究 .................................................................................. 38

§4.4.1.1 压力分布 .............................................................................. 38

§4.4.1.2 流场分布 .............................................................................. 40

§4.4.1.3 湍流动能分布 ...................................................................... 41

§4.4.2 实际尺寸模型研究 ......................................................................... 42

§4.4.2.1 一级冷却 ............................................................................... 42

§4.4.2.2 多级冷却 .............................................................................. 51

§4.4.3 微尺寸模型研究 ............................................................................. 55

§4.4.3.1 温度分布 ............................................................................... 56

§4.4.3.2 湿度分布 ............................................................................... 58

§4.5 温度场、湿度场和速度场的耦合作用分析 ............................................ 63

§4.6 本章小结 .................................................................................................... 64

第五章 模拟和实验数据处理及分析 ....................................................................... 65

§5.1 模拟和实验数据比较 ................................................................................ 65

§5.2 不同工况实验数据对比 ............................................................................ 66

§5.2.1 半系统不同湿度实验结果对比 ..................................................... 66

§5.2.2 全系统不同湿度实验结果对比 ..................................................... 70

§5.3 蒸发冷却器性能的评价指标 .................................................................... 75

§5.3.1 湿球效率 ......................................................................................... 75

§5.3.2 露点效率 ......................................................................................... 75

§5.3.3 两种布水运行方式的效率 ............................................................. 76

§5.3.3.1 半系统运行方式的效率 ...................................................... 76

§5.3.3.2 全系统运行方式的效率 ...................................................... 76

§5.3.3.3 两系统的效率对比 .............................................................. 77

§5.4 多级露点式蒸发冷却模拟结果效率对比 ................................................ 79

§5.5 本章小结 .................................................................................................... 81

第六章 结论与展望 ................................................................................................... 82

§6.1 结论 ............................................................................................................ 82

§6.2 本论文创新点 ............................................................................................ 83

§6.3 展望 ............................................................................................................ 83

参考文献 ..................................................................................................................... 85

附录 实验与模拟数据汇总 ....................................................................................... 88

在读期间公开发表论文和承担科研项目及取得成果 ............................................. 90

致谢 ............................................................................................................................. 91

第一章 绪论

1

第一章 绪 论

§1.1 课题研究背景

§1 .1.1 蒸发冷却技术的发展历史

据史料记载,蒸发冷却的概念最早出现于公元前 2500 年左右,古埃及人发现

将水放入多孔陶罐并置于空气流通的地方会有使空气变凉爽的作用。这种原型装

置普遍存在于古埃及的建筑中。后来该方法很快流传到气候干燥炎热的中东地区,

随之出现了很多类似的衍生装置,比如建筑下层的小水池等,这些装置与当时的建

筑结构相融合,其目的就是为了达到通过空气流通使水池内的水蒸发,从而达到降

低建筑物内空气温度的效果。

现代蒸发冷却技术的运用最早现于二十世纪初叶的美国新英格兰和南部海岸

线地区,这种技术普遍应用于对空气湿度有要求的纺织工厂[1]。与此同时,多种不

同的直接或间接蒸发冷却装置现于西南部的亚利桑那州和加利福尼亚州。在二十

世纪 30 年代末,西南部地区的许多工厂和住宅建筑都安装了单独的滴水式空气冷

却装置,这种装置于 50 年代初实现了批量化生产,其使用范围已经覆盖了美国、

加拿大和澳大利亚等[2]。这种装置所运用到的原理就是直接式蒸发冷却技术,由于

其低能耗的特点在一定地区内得到广泛应用。

间接蒸发冷却技术是在直接蒸发冷却基础上产生的。和直接蒸发冷却技术相比,

它有一个很突出优点,即前者不会增加所处理空气的湿度。于是在过去的半个世纪,

这种空气处理技术得到快速而巨大的发展与应用。

在全球的建筑能耗居高不下,而降低碳排放量又迫在眉睫的当代,开发新的能

源与新的空气处理方式用以替代传统的制冷剂和制冷方式,已经成为广大科研工

作者的热门课题。显然,如果能继承古人对于自然工质的运用能力,结合当代的先

进生产制作工艺和理念,在保持这种技术的环境友好特性的同时,也达到更好的空

气处理效果,将会使当代人类取得保护环境和营造舒适居住条件“双赢”的结果。

§1 .1.2 露点式蒸发冷却技术的提出及研究

为了加强间接蒸发冷却换热器的制冷效果,2003 年Valeriy Maisotenko 教授[3]

提出了一种新式的理想化的换热方式,并以自己的名字将这种换热方式命名为 M-

循环(M-cycle)。依据这种换热方式设计并制造了一种装置用于空气冷却处理。该

装置的原理是基于直接蒸发冷却和间接蒸发冷却的组合与改造。

上海理工大学硕士学位论文

2

这种装置优点突出。首先,不设置压缩机,仅仅使用风机为装置内的空气流动

提供动力。这使得其耗电量比普通的空调机节省电量约 80%,这对于需要全天候

运行的单位来说,使他们可以在节省大笔运行管理费用的同时,保持室内持续稳定

的温湿度环境。其次,不使用 CFC 类制冷剂,而是使用自然界存在的水作为冷源,

通过水的蒸发作用完成与空气之间的热量传递。该过程中没有任何污染环境的物

质排出,甚至没有二氧化碳排放。第三,节约用水量。它的主要原理是利用水蒸发

时吸收大量的潜热,而不仅仅是使用水与空气之间的温差进行显热交换。有研究显

示这种装置与大型的冷却塔相比可以节省约 50%的用水量。最后,初投资低。由于

其结构与大型冷却塔相比要小的多,原理清晰,处理过程简单,对于安装环境的要

求少,所以它的适用范围与大型冷却塔相比要大,初投资低,后期的运营维护费用

也要少很多。

由于露点式蒸发冷却技术,具有上述若干优点,同时补充了原有的两种蒸发冷

却的不足,使其在制冷和空气调节领域成为一种相当有发展潜力的技术,在空气调

节领域内有较多的应用。

§1 .1.3 蒸发冷却技术在空气调节领域的应用

露点式蒸发冷却技术虽然具有高能效、无 CFC 及CO2排放、节水节电节约能

源、低初投资的优点,但由于受到外界环境因素的影响大,蒸发冷却技术的应用会

受到一定的限制。以往蒸发冷却技术的应用除少数对空气湿度有要求的用户(如纺

织厂等),其余多数都是作为空气的预处理阶段进行的。比如与冷却塔的结合应用、

空气加湿降温段等的应用。据调查研究报告显示,在伊朗的部分地区,蒸发冷却系

统无法在炎热的气候达到令人满意的效果,在该地区间接蒸发冷却一般是作为二

次空气的处理步骤。另外还有把蒸发冷却和蒸汽压缩式制冷机组结合应用,将蒸发

冷却段作为入口空气的预处理手段,这样可以提高蒸汽压缩式制冷的效率。

露点式蒸发冷却的出现,使得该项技术的应用范围有所扩展。有实验研究表明,

这种技术可以单独运用于空气调节领域并取得相当好的处理效果,其效率与间接

蒸发冷却相比可以提高 16.7%[4]。在该项技术的运用上,美国走在了世界的前列[5],

Coolerado Cooler 公司生产了一种结构类似于 M-cycle 概念的蒸发冷却器,其处理

过的空气湿度比直接蒸发冷却后的空气湿度要低,比间接蒸发冷却后的空气温度

要低,这种装置已经生产并在各大注重环保节能的用户处投入使用。与此同时,印

度也在进行相类似结构的开发。

在中国,露点式蒸发冷却还出于研发阶段。有学者研究表明[6-8],蒸发冷却技术

在中国除少数高温高湿地区不适宜使用外,大多数地区都能取得令用户满意的结

第一章 绪论

3

果。

§1 .2 国内外研究现状

§1 .2.1 露点式蒸发冷却结构形式的研究

露点间接蒸发冷却起源于 20 世纪 60 年代。Maisotsenko[9]等提出一种不使用压

缩机或任何化合类制冷剂的新热力循环,可以使任何一种气、液冷却到湿球温度下,

直至达到露点温度。其原理是将直接蒸发和间接蒸发相结合,将经过间接蒸发换热

的一次空气通过通道间的小孔通入直接蒸发通道,继续冷却两通道间的隔板,从而

使间接蒸发后得到的空气温度更低。理想情况下,经过足够多级的冷却可以接近或

达到空气的露点温度。运用这种理论,他们得到一种发明专利的授权——用于露点

蒸发冷却器的方法和板装置。

Bong Su Choi[10]等对不同结构类型的再生式蒸发冷却器进行了优化,其中肋片

式再生蒸发冷却器的显著特点为结构紧凑,体积约为平板式的 1/8。荷兰奥赛康节

能空调技术设备有限公司出品了一种 OXYCELL 空气交换器,也同样代表了露点

蒸发冷却技术的一个发展阶段。

英国诺丁汉大学赵旭东[11]等对该技术进行了详细的数值模拟研究。他们以用于

露点蒸发冷却的一种新型逆流换热器为对象,做了详细的模拟,结果显示影响系统

冷却效率和能效的主要因素为流道尺寸、气流速度及工作气体流量与进气量之比,

而供水温度的影响相对较小。

J.A.M 赖因德斯[12]等申请了一种露点冷却器的专利,该冷却器包括两个相互连

接的介质回路。

W梅杰[13]的露点冷却设备有若干个冷却通道,该冷却通道设置有待冷却气流

入口和已冷却气流出口,有若干个蒸发通道,独立于冷却通道,且蒸发通道具有流

入流出开口,其流入开口连接在冷却通道的流出开口之后,湿润传导壁朝向蒸发通

道一侧。该装置特点在于对冷却通道的气流进行除湿处理。

麦索特森科[14]申请了一种用于露点蒸发冷却器的方法和板装置的发明专利。此

专利是在 Maisotsenko 的专利基础上加以改进形成的。

我国对蒸发冷却应用的研究开始于 20 世纪 70 年代。最早由陈沛霖教授将蒸发

冷却引入我国。同济大学的陈沛霖教授[15-16]选择遍布全国的 77 个城市,根据有关

规范规定的气象资料进行计算,绘出了夏季设计条件下和最热月平均条件下应用

间接蒸发冷却技术的地图分界线和送风温度分布图,为我国各地区间接蒸发冷却

相关推荐

-

生态农业项目商业计划书VIP免费

2024-12-31 30

2024-12-31 30 -

牛奶创业计划书VIP免费

2024-12-31 6

2024-12-31 6 -

南京现实版开心农场VIP免费

2024-12-31 8

2024-12-31 8 -

绿色蔬菜农产品批发创业计划书VIP免费

2024-12-31 10

2024-12-31 10 -

绿色农产品销售创业计划书VIP免费

2024-12-31 8

2024-12-31 8 -

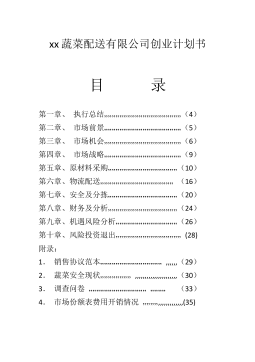

xx蔬菜配送有限公司创业计划书样本VIP免费

2025-01-09 5

2025-01-09 5 -

现代农业生态园创业计划书范文VIP免费

2025-01-09 12

2025-01-09 12 -

农场创业计划书模板VIP免费

2025-01-09 17

2025-01-09 17 -

奉节县特色农产品电子商务创业计划书模板VIP免费

2025-01-09 13

2025-01-09 13 -

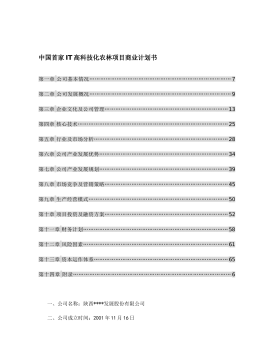

中国首家IT高科技化农林项目商业计划书VIP免费

2025-01-09 11

2025-01-09 11

作者:侯斌

分类:高等教育资料

价格:15积分

属性:96 页

大小:9.62MB

格式:PDF

时间:2025-01-09