微污染地表水处理工艺试验研究与工程应用

VIP免费

摘 要

随着水源污染不断加剧,目前大冶水库水出现了氨氮、藻类等指标超标的现

象,严重威胁饮用水水质安全和人体健康。莱芜城源净水厂是以大冶水库作为饮

用水水源地,目前净水厂主要是采用常规工艺处理,即混凝沉淀、过滤和消毒,

从检测结果来看,现有处理工艺难以满足水库水受污染时水质变化的需求,尤其

是夏季,经常出现嗅味、NH3-N 等超标的现象,因此,研究和应用先进的饮用水

深度处理工艺是非常有必要的。

根据水库水质的特点,通过常规混凝、强化混凝、预氧化后混凝以及臭氧-活

性炭深度处理对水库水进行试验研究,重点考察不同处理方法对水库水的处理效

果,在试验中得到最佳处理工艺参数,并对该工程进行初步设计和成本分析。

通过对水库水的检测分析发现,原水水质污染较严重,CODMn 在3.36~

6.64mg/L 之间,NH3-N 平均值为 1.41mg/L,已严重超过国家地表水Ⅲ类标准。原

水在夏季呈现高浊度、高藻类的特性,且在试验过程中发现原水中会出现一些白

色粘稠状物质,经 GC-MS 检测,该类物质是硅氧烷类有机物。

水厂目前主要采用常规处理,从运行效果分析来看,对于 CODMn 和NH3-N 去

除效果并不好,尤其是对一些可溶解性有机物去除能力有限,对于浊度和藻类的

去除效果明显,对原水中的硅氧烷类物质去除效果不佳。

通过小试试验确定最佳混凝剂及其投加量,PAC 投加 8mg/L 时,各指标去除

效率最高。后续试验研究了投加助凝剂 PAM、臭氧预氧化以及高锰酸钾预氧化对

原水的处理效果,结果表明,投加 PAM 为0.4mg/L 时,CODMn、UV254、NH3-N

和浊度的去除率最高,分别为 20.22%、26.76%、14.49%和32.38%;臭氧投加量为

1mg/L 时,CODMn、UV254、NH3-N 和浊度去除率分别为 17.86%、28.51%、12.50%

和31.30%;高锰酸钾投加量为 0.8mg/L 时,CODMn、UV254、NH3-N 和浊度的去除

率分别为 32.64%、36.24%、16.99%和41.69%,是所有方法中处理效果最好的,且

试验中发现高锰酸钾预氧化对于硅氧烷类物质有较好的去除。

深度处理工艺采用臭氧活性炭,主臭氧最佳投加量为 2.5mg/L,接触时间为

10min 时,各指标去除率最高,通过长时间连续性试验运行发现,高锰酸钾预处理

+常规处理+O3-活性炭工艺对该水库水中的有机物、藻类等有较稳定的去除效果,

常规检测指标能满足国家饮用水标准。

水厂设计水量为 5万m3/d,新建气浮接触池、臭氧活性炭滤池,工程总投资

为3293.67 万元,其中建筑工程费用 1212.97 万元,设备投资费用为 870.14 万元,

工程设备安装费用为 223.09 万元,其他费用共计 302.69 万元。运营期内单位处理

总成本为 0.25 元/吨,单位经营成本为 0.14 元/吨,项目回收期为 9.29 年,总投资

收益率为 8.11%,资本金净利润率为 6.15%,生产能力利用率为 52.52%,各经济

指标均符合行业标准。

关键词:微污染原水 强化混凝 预氧化 臭氧-活性炭

ABSTRACT

With the intensification of water pollution, the characterics of Daye reservoir water

was with high ammonia nitrogen, high algae, which has threatened the safety of

drinking water and people health seriously. Cheng-yuan water plant in LaiWU, with the

Daye reservoir water as water resource, uses conventional technology, namely,

coagulation sedimentation, filtration and disinfection. From the test results, the

traditional water treatment can not meet the demand of quality changes of original water,

especially in summer, often appear the phenomenon of smelling, high ammonia nitrogen

etc. So it is necessary to study and applicate the advanced drinking water treatment

technologies to access to high quality drinking water.

According to the characterics of the reservoir water quality, through conventional

coagulation, strengthening coagulation, pre-ozone oxidation, ozone/activated carbon

treatment, treatment effect of the reservoir water on different methods were studied and

the best treatment parameters were put forward by experiments. The preliminary design

and cost analysis was done for the project.

The reservoir water was seriously polluted by organic pollutants. The CODMn of

the raw water was 3.36~6.64mg/L, the ammonia nitrogen was 1.41mg/L on the

average, which was serious more than the national surface water Ⅲ class standard. The

raw water characterics was with high turbidity and high algae in summer. A few white

sticky was found in the raw water, which was organic polydimethy siloxane through

GC-MS detection.

The conventional process for CODMn and ammonia nitrogen removal effect was

not good, especially for some limited ability to removal dissolved organic water, the

process has obvious removal effect for turbidity and algae, but it was ineffective for the

removal of siloxane materials in raw water.

The optimal coagulant dosage was determined by jar test, when PAC dosage was

8mg/L, each indicator was on the highest removal efficiency. The impacts of PAM, the

pre-oxidation of potassium permanganate and ozone on the raw water were studied. The

results showed that when PAM dosage was 0.4mg/L, CODMn, UV254, ammonia nitrogen,

turbidity removal were 20.22%, 26.76%, 14.49% and 32.38%. When ozone dosage was

1mg/L, the removal of CODMn, UV254, ammonia nitrogen, turbidity were 17.86%,

28.51%, 12.50% and 31.30%. When potassium permanganate dosage was 0.8mg/L,

CODMn, UV254, ammonia nitrogen, turbidity removal were 32.64%, 36.24%, 16.99%

and 41.69%. The pre-oxidation of potassium permanganate was the best method of the

treatment and effective removal for the siloxane materials in raw water. Therefore the

potassium permanganate was the pretreatment process in the experiments.

The ozone activated carbon treatment technology was used on filtered water. The

resulted showed that the optimal dosage of ozone was 2.5mg/L and the reaction time

was 10min. Through long continuity test, potassium permanganate pretreatment,

conventional treatment and ozone-carbon process had the stable removal for the organic

matter, algae etc. The testing indicators could meet the effluent quality standards.

The water plant design was 50000m3/d, air flotation contact tank and ozone

activated carbon filter were new constructed. The total investment was 32.9367 million

yuan, of which 12.1297 million yuan construction installation, 8.7014 million yuan

investment in equipment, engineering equipment installation cost 2.2309 million yuan

and other expenses totaling was 3.0269 million yuan. The total cost of operating units

during the processing was 0.25 Yuan/ton, the unit operating cost was 0.14 Yuan/ton, the

project payback period is 9.29 years, the total investment yield is 8.11%, the net captital

ratio is 6.15%, the production capacity utilization is 52.52%, all the economic indicators

are in line with industry standards.

Key Word: micro-pollution water, enhanced coagulation, pre-oxidation,

ozone-activated carbon

目 录

中文摘要

ABSTRACT

第一章 绪论 ......................................................... 1

1.1 我国水资源现状 ................................................ 1

1.2 地表水污染防治对策 ............................................ 1

1.2.1 提高饮用水水质标准 ........................................ 1

1.2.2 提高工艺处理能力 .......................................... 2

1.3 地表水处理方法与技术 .......................................... 2

1.3.1 常规混凝 .................................................. 2

1.3.2 强化混凝 .................................................. 3

1.3.3 预处理 .................................................... 4

1.3.4 深度处理 .................................................. 8

1.4 研究目的和内容 ............................................... 10

1.4.1 研究目的 ................................................. 10

1.4.2 研究内容 ................................................. 11

1.4.3 创新点 ................................................... 11

第二章 实验装置及研究方法 .......................................... 13

2.1 实验场所及水源地 ............................................. 13

2.2 水质指标分析方法 ............................................. 13

2.3 试验仪器及试验药剂 ........................................... 15

第三章 水库水质分析与现状处理工艺研究 .............................. 16

3.1 CODMn ......................................................... 16

3.1.1 原水 CODMn 变化趋势 ......................................... 16

3.1.2 现工艺对 CODMn 去除 ......................................... 16

3.1.3 解决方法 ................................................. 17

3.2 UV254 .......................................................... 17

3.2.1 原水 UV254 变化趋势 ......................................... 17

3.2.2 现工艺对 UV254 去除 ......................................... 18

3.2.3 解决方法 ................................................. 19

3.3 NH3-N ......................................................... 19

3.3.1 原水 NH3-N 变化趋势 ........................................ 19

3.3.2 现工艺对 NH3-N 去除 ........................................ 19

3.3.3 解决方法 ................................................. 20

3.4 浊度 ......................................................... 20

3.4.1 原水浊度变化趋势 ......................................... 20

3.4.2 现工艺对浊度去除 ......................................... 21

3.4.3 解决方法 ................................................. 21

3.5 藻类 ......................................................... 22

3.5.1 原水藻类变化趋势 ......................................... 22

3.5.2 现工艺对藻类去除 ......................................... 22

3.5.3 解决方法 ................................................. 23

3.6 有机物种类 ................................................... 23

3.6.1 XRD 分析图 ................................................ 23

3.6.2 原水 GC-MS 分析图 ......................................... 24

3.6.3 现工艺对污染物去除分析 ................................... 24

3.6.4 解决方法 ................................................. 26

3.7 本章小结 ..................................................... 26

第四章 预处理工艺处理水库水试验研究 ................................ 28

4.1 试验方法 ..................................................... 28

4.2 混凝去除效果 ................................................. 28

4.2.1 有机物的去除 ............................................. 28

4.2.2 浊度的去除 ............................................... 28

4.2.3 NH3-N 的去除 .............................................. 29

4.2.4 UV254 的去除 ................................................ 29

4.3 强化絮凝处理工艺的去除效果 ................................... 30

4.3.1 CODMn 和UV254 的去除 ......................................... 30

4.3.2 浊度的去除 ............................................... 31

4.3.3 NH3-N 的去除 .............................................. 31

4.4 预氧化+常规处理工艺的去除效果 ................................ 32

4.4.1 KMnO4预氧化 ............................................... 32

4.4.2 预臭氧+PAC ............................................... 35

4.5 预处理方法的确定 ............................................. 38

4.6 本章小结 ..................................................... 38

第五章 臭氧与活性炭深度处理试验研究 ................................ 40

相关推荐

-

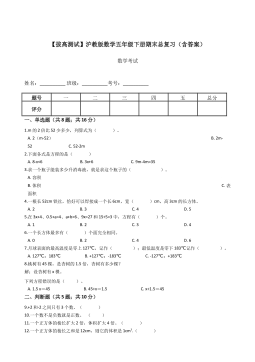

【拔高测试】沪教版数学五年级下册期末总复习(含答案)VIP免费

2024-11-19 13

2024-11-19 13 -

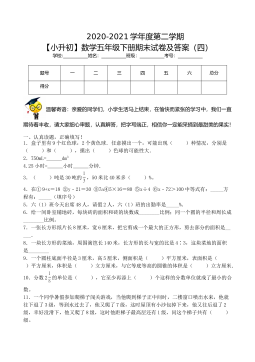

【基础卷】小学数学五年级下册期末小升初试卷四(沪教版,含答案)VIP免费

2024-11-19 8

2024-11-19 8 -

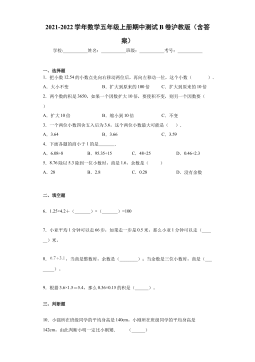

期中测试B卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 8

2024-11-19 8 -

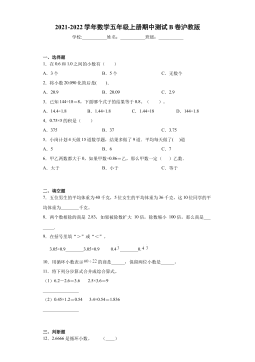

期中测试B卷(试题)- 2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 10

2024-11-19 10 -

期中测试A卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 14

2024-11-19 14 -

期中测试A卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 15

2024-11-19 15 -

期中测B试卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 11

2024-11-19 11 -

期中测A试卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 22

2024-11-19 22 -

【七大类型简便计算狂刷题】四下数学+答案

2025-03-18 6

2025-03-18 6 -

【课内金句仿写每日一练】四下语文

2025-03-18 6

2025-03-18 6

作者:侯斌

分类:高等教育资料

价格:15积分

属性:70 页

大小:2.86MB

格式:PDF

时间:2025-01-09

相关内容

-

期中测试A卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

期中测B试卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

期中测A试卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

【七大类型简便计算狂刷题】四下数学+答案

分类:中小学教育资料

时间:2025-03-18

标签:数学计算;校内数学

格式:PDF

价格:1 积分

-

【课内金句仿写每日一练】四下语文

分类:中小学教育资料

时间:2025-03-18

标签:无

格式:PDF

价格:1 积分