铁改性活性炭吸附水中镉的实验研究

VIP免费

摘 要

我国水体重金属污染日益严重,镉作为毒性最强的重金属污染物之一,通过

食物链的富集作用可在人体肝、肾内蓄积,严重威胁人类健康,重金属污染治理

刻不容缓。活性炭吸附法具有高效、经济、易操作等特点,是有效去除水中污染

物的一种方法,但其对镉的吸附容量有限,为增加其吸附能力及吸附稳定性,需

要对活性炭进行改性。研究发现,将铁氧化物负载到活性炭上制备出新型复合吸

附材料,对水中的重金属具有良好的去除效果。当前对于铁氧化物改性活性炭的

研究,多为处理水中有机物、砷和铬等污染物,对处理水中阳离子重金属特别是

镉的研究较少,且研究多集中于对污染物的静态吸附性能,而对动态吸附特性以

及实际废水中的应用研究较少。

针对以上问题,本文通过负载铁氧化物改性活性炭,制备一种对水中的 Cd2+

具有良好吸附性能且具有一定机械强度的吸附剂,进行 Cd2+的静态和动态吸附实

验以及材料表征,研究其对 Cd2+的吸附特性和吸附机理,并探索其对实际河道水

中Cd2+的吸附效果,为铁改性活性炭吸附剂处理水中重金属的实际应用提供一定

的理论依据。主要研究内容和结论如下:

(1) 在铁改性活性炭制备方法筛选实验中,采用三价铁盐和二价铁盐在不

同的反应条件下制备不同的铁改性活性炭,对比其对水中 Cd2+的吸附效果,得出

采用 Fe2(SO4)3在NaOH 溶液中沉淀,制得的铁改性活性炭对 Cd2+的去除率较好。

研究不同的载铁量对活性炭吸附性能的影响,得出铁改性活性炭的最佳载铁量为

17.59%,此材料标记为 Fe-AC2。由 SEM 和BET 结果得出,Fe-AC2 表面附着有

些许铁氧化物颗粒,比表面积和孔容分别为 962.95 m2/g、0.4981 cm3/g,相比 AC

均有降低。由 FTIR 图谱分析知,3437 cm-1 附近-OH 的吸收峰加强,613 cm-1 处有

较强烈的 Fe-O 吸收峰,证明铁氧化物成功负载到活性炭上。XRD 图谱上没有明显

的晶体衍射峰,可知活性炭表面负载的铁以非晶态铁氧化物的形式存在。

(2) 在静态吸附实验中,考察了 pH 和初始浓度对 Fe-AC2 吸附 Cd2+的影响。

结果表明,低 pH 条件下,活性炭上负载的铁有脱落现象,溶液 pH 在5~7 范围内,

Fe-AC2 对Cd2+具有较好的吸附效果。在一定浓度范围内,Fe-AC2 对Cd2+的吸附

量随着溶液中 Cd2+初始浓度的增加而增加,Fe-AC2 对Cd2+的吸附量远大于 AC。

进行等温模型拟合发现,Freundlich 等温模型拟合中 1/n 的值介于 0.1~0.5,表明

Fe-AC2 易于吸附溶液中的 Cd2+。Langmuir 模型比 Freundlich 模型能更好地描述

Fe-AC2对Cd2+的吸附行为,其拟合系数为 0.99,对 Cd2+的最大吸附量为 5.10 mg/g,

相比 AC,提高了约 487%。

(3) 在动态吸附柱实验中,考察了进水 pH、流速、初始浓度和吸附柱填料

高度等因素对动态吸附过程的影响。结果表明,进水 pH 在4~6 范围内时,Fe-AC2

对Cd2+的吸附能力随着 pH 的增加而增大。较大的流速、较高的初始浓度和较小的

填料高度均会加速 Fe-AC2 吸附柱的穿透进程,缩短穿透时间。与静态吸附实验结

论一致,Fe-AC2 对Cd2+的吸附容量随着浓度的增加而增加,较高的浓度梯度,有

利于扩散系数或传质系数的增加,传质推动力增大,导致 Cd2+的去除率也增加。

同时对实验结果进行拟合得出,Adams-Bohart 模型不适合描述 Fe-AC2 对Cd2+的

动态吸附过程,BDST 模型和 Thomas 模型的拟合系数相对较好,拟合曲线与实际

穿透曲线基本吻合,其拟合参数可以为吸附柱的工业化应用提供一定的参考信息。

当初始浓度为 1 mg/L、流速为 4.5 mL/min、填料高度为 13.5 cm 时,Fe-AC2 对Cd2+

的Thomas 模型拟合饱和吸附容量约为 0.57 mg/g,低于静态实验的吸附量,这可

能与系统达到吸附平衡的方式不同有关。此外,分别用 AC 和Fe-AC2 吸附柱对河

水中的 Cd2+的进行动态吸附实验,得出 AC 对河水中的 Cd2+几乎没有吸附效果,

载铁改性后,Fe-AC2 对河水中 Cd2+的吸附效果得到了显著提升,与处理模拟废水

相比,Fe-AC2 吸附柱对 Cd2+的吸附能力有所提高,这可能是由于河水的 pH 较高

及河水中存在的无机盐或有机物的存在促进 Cd2+的吸附。

(4) 通过吸附实验数据及材料表征分析,可以推断 Fe-AC2 对Cd2+的吸附

过程存在多种吸附机理,既有物理吸附,又有离子交换和化学吸附。Fe-AC2 对Cd2+

吸附量的增加主要是因为 Cd2+与Fe-AC2 上负载的铁氧化物发生了表面络合反应。

关键词:活性炭 铁氧化物 镉 静态吸附 动态吸附

ABSTRACT

Heavy metal pollution in aquatic environment is becoming increasingly serious in

China. Cadmium, as one of the most toxic heavy metals, can accumulate in human liver

and kidney through food chains. The removal of toxic metals from water is a matter of

great interest because it poses a great threat to human health. Adsorption by activated

carbon is accepted to be the best available technology for the removal of pollutants in

water because it is efficient, economical and easy to operate. The adsorption capacity of

activated carbon for cadmium is low, therefore, required to do some modification on

activated carbon to increase its adsorption capacity and stability. Researchers found that

activated carbon modified by iron oxide has a good removal of heavy metals in water.

Nowadays, studies on iron oxide modified activated carbon are mainly about the

removal of organic pollutants, arsenic, chromium and other pollutants in water. Studies

on removal of heavy metal cations especially cadmium by iron oxide modified activated

carbon are relatively few. Furthermore, the studies are mostly focused on batch

adsorption of pollutants rather than column adsorption and applications in wastewater

treatment.

In view of the questions above, this paper prepared an activated carbon modified

by iron oxide which has certain mechanical strength and good adsorption performance

for cadmium removal from water. Then the adsorption properties and mechanism of the

iron modified activated carbon was researched by batch and column adsorption

experiments combined with the characterization of materials. Moreover, the material

was used to remove cadmium from river, in order to provide a theoretical basis for the

practical application of iron modified activated carbon. The main contents and

conclusions of this paper are as follows:

Firstly, several iron modified activated carbons are prepared by ferrite and ferrous

salts respectively in different conditions. The results show that the activated carbon

modified by Fe2(SO4)3 precipitated in NaOH solution has a better removal of Cd2+.

Effects of different loaded iron contents are investigated. The optimal iron content

loaded on activated carbon is 17.59% and the material is remarked as Fe-AC2. SEM

and BET results show that some iron oxide particles are attached to its surface. The

specific surface area and pore volume of Fe-AC2 is 962.95 m2/g and 0.4981 cm3/g

respectively which is decreased compared with AC. FTIR spectrum show characteristic

peak near 3437 cm-1 corresponded to –OH and 613 cm-1 corresponded to Fe-O proved

the existing of FeOOH on Fe-AC2. No diffraction peak is observed on XRD spectrum

which suggests that the loaded iron of Fe-AC2 mainly exists in the form of amorphous

iron oxide(FeOOH).

Secondly, the effects of pH and initial concentration on the removal of Cd2+ by

Fe-AC2 are studied in batch adsorption experiments. The results show that loaded iron

could fall down from Fe-AC2 when the pH was low. Fe-AC2 has good adsorption effect

on Cd2+ when the pH is ranged from 5 to 7. In a certain range of concentration, the

adsorption capacity of Cd2+ on Fe-AC2 increases with the increasing initial

concentration and the adsorption capacity is higher than AC. Freundlich adsorption

isotherm fit the adsorption process well when 1/n value between 0.1~0.5, which means

that the adsorption in solution can easily occur. Langmuir adsorption isotherm fitting is

better than that of Freundlich adsorption isotherm with R2=0.99. The maximum

adsorption capacity of Fe-AC2 is 5.10 mg/g improved about 487% compared with AC.

Thirdly, effects of pH, flow rate, initial concentration and bed height are

investigated in column adsorption process. When pH is in the range of 4~6, the

adsorption capacity of Cd2+ on Fe-AC2 increase with the increase of pH. With higher

velocity, larger initial concentration, smaller bed height, the penetrating process of

Fe-AC2 column can be faster and the breakthrough time can be shorter. In accordance

with batch adsorption experiment, the adsorption capacity of Cd2+ on Fe-AC2 increase

with the increasing concentration. As the feed concentration increases, metal loading

rating increases, but so does the driving force for mass transfer, which leads to the

increase of Cd2+ removal rate. By fitting the experimental results, we can see that

Adams-Bohart model is not suitable to describe the dynamic adsorption process of Cd2+

on Fe-AC2, while the fitting coefficients of BDST model and Thomas model are

relatively good. The fitting curves are almost consistent with the actual breakthrough

curves which can provide a certain reference for industrial application of the adsorption

column. The saturated adsorption capacity for 1 mg/L feed concentration of Cd2+ at flow

rate of 4.5 mL/min and 13.5 cm bed height is found to be 0.57 mg/g according to

Thomas model, which indicates that column adsorption capacity of Fe-AC2 is far less

than batch mode results. This may be due to the potential irreversibility of the sorption

process and the different approaches to adsorption equilibrium in different systems. In

addition, AC and Fe-AC2 are used to remove Cd2+ from Fuxingdao river. Results show

that AC has no effect on Cd2+ removal, while the adsorption capacity of Fe-AC2 has

been significantly improved which is higher than that of simulated wastewater treatment.

This may due to the high pH in Fuxingdao river, moreover, the exist of inorganic salts

or organics may benefit the adsorption of Cd2+.

Finally, combined with the adsorption experiment and characterization of materials,

we can inffer that there are several mechanisms in the adsorption process of Cd2+,

including physical adsorption, ion exchange and chemical adsorption. The increase of

adsorption capacity of Fe-AC2 is mainly due to the reaction between Cd2+ and iron

oxide loaded on Fe-AC2.

Key Word: activated carbon, iron oxide, cadmium, batch adsorption,

column adsorption

目录

中文摘要

ABSTRACT

第一章 绪 论...............................................................................................................1

1.1 我国水体中重金属污染现状............................................................................1

1.1.1 重金属的污染来源及危害 .......................................................................1

1.1.2 水中重金属污染治理方法.........................................................................3

1.2 改性活性炭吸附水中重金属研究现状............................................................5

1.2.1 活性炭的性质.............................................................................................5

1.2.2 活性炭改性及去除重金属的研究.............................................................6

1.3 铁氧化物吸附水中重金属研究现状................................................................9

1.4 研究目的和主要内容......................................................................................11

1.4.1 研究目的与意义.......................................................................................11

1.4.2 研究内容...................................................................................................12

第二章 材料与方法...................................................................................................13

2.1 实验试剂与仪器..............................................................................................13

2.1.1 实验原料和试剂.......................................................................................13

2.1.2 实验设备及检测仪器...............................................................................13

2.2 实验方法................................................... ......................................................14

2.2.1 活性炭改性方法.......................................................................................14

2.2.2 静态吸附实验...........................................................................................15

2.2.3 动态吸附实验...........................................................................................16

2.3 分析方法..........................................................................................................18

2.3.1 等温吸附模型...........................................................................................18

2.3.2 吸附柱操作参数的计算...........................................................................19

2.3.3 穿透曲线的模型拟合...............................................................................20

第三章 铁改性活性炭的制备与表征.......................................................................22

3.1 铁改性活性炭的制备......................................................................................22

3.1.1 铁改性活性炭制备方法筛选...................................................................22

3.1.2 铁改性活性炭制备方法优化...................................................................23

3.2 铁改性活性炭材料表征..................................................................................24

3.2.1 零电荷点(pHpzc)测定.........................................................................24

3.2.2 比表面积及孔结构...................................................................................24

相关推荐

-

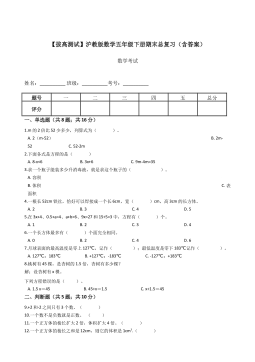

【拔高测试】沪教版数学五年级下册期末总复习(含答案)VIP免费

2024-11-19 13

2024-11-19 13 -

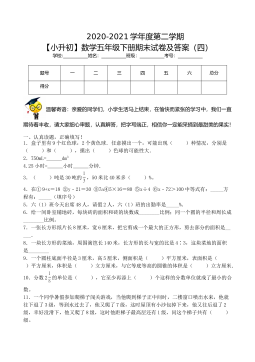

【基础卷】小学数学五年级下册期末小升初试卷四(沪教版,含答案)VIP免费

2024-11-19 8

2024-11-19 8 -

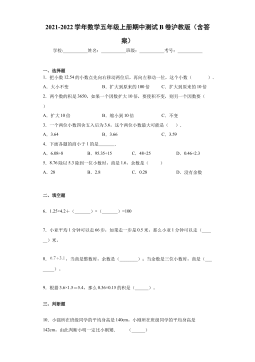

期中测试B卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 8

2024-11-19 8 -

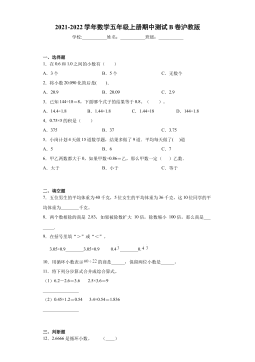

期中测试B卷(试题)- 2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 10

2024-11-19 10 -

期中测试A卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 14

2024-11-19 14 -

期中测试A卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 15

2024-11-19 15 -

期中测B试卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 11

2024-11-19 11 -

期中测A试卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 22

2024-11-19 22 -

【七大类型简便计算狂刷题】四下数学+答案

2025-03-18 6

2025-03-18 6 -

【课内金句仿写每日一练】四下语文

2025-03-18 6

2025-03-18 6

作者:侯斌

分类:高等教育资料

价格:15积分

属性:66 页

大小:3.41MB

格式:PDF

时间:2025-01-09

相关内容

-

期中测试A卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

期中测B试卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

期中测A试卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

【七大类型简便计算狂刷题】四下数学+答案

分类:中小学教育资料

时间:2025-03-18

标签:数学计算;校内数学

格式:PDF

价格:1 积分

-

【课内金句仿写每日一练】四下语文

分类:中小学教育资料

时间:2025-03-18

标签:无

格式:PDF

价格:1 积分