热固性含氟聚氨酯的可控制备及其在特种涂料中的应用

VIP免费

摘 要

本论文首先利用自制的含氟聚醚多元醇(FPO)与二苯基二异氰酸酯(MDI)、

交联剂三乙醇胺合成了热固性含氟聚氨酯(以下简称 S-FPU)。在确定 S-FPU 化

学结构的基础上,采用旋转流变仪测定了 S-FPU 凝胶化时间。通过与相似结构的

热固性聚氨酯(以下简称 S-PU)进行对比,发现相同固化温度下 S-FPU 的凝胶

化时间比 S-PU 的凝胶化时间要短。对固化物的三维网状结构进行分析表明,相

同条件下,S-FPU 的交联密度高于 S-PU。这均说明 F对S-FPU 的交联网状结构

的形成具有促进作用。本论文通过 X光电子能谱(XPS)并结合 Ar 离子刻蚀技

术进一步研究了 S-FPU 表面结构控制。结果表明,通过调控原料配比、FPO 结构、

硬段含量、固化温度等可实现含氟侧链的表面迁移和富集性。降低 S-FPU 交联密

度,减小软段含氟侧链的运动位阻,降低 S-FPU 固化温度,有利于 S-FPU 中的含

氟侧链向表面迁移和富集。S-FPU 表面特性测量结果显示,表面 F含量越高,其

表面接触角越大,疏水性越强。本论文还通过热重分析对比了 S-FPU、S-PU、热

塑性含氟聚氨酯(以下简称 P-FPU)的热稳定性,研究发现软段侧链氟密度越大,

硬段含量越高,S-FPU 的热稳定性越好,S-FPU 的热稳定性均高于 S-PU、P-FPU。

在S-FPU 表面结构控制研究的基础上,本论文根据重防腐涂料的配方指导原

则,选择了具有片层结构的防腐颜料与 FPO、MDI 配伍,并选择了环境友好型混

合溶剂制备了双组份溶剂型 S-FPU 涂料。根据国标对涂膜表面性能、耐水性、耐

盐雾性能等测试评价证明了,表面氟含量与 S-FPU 涂膜的表面性能、耐水性、耐

盐雾性能等的关系,即表面氟含量越高,涂膜的耐蚀性越好;S-FPU 涂膜的疏水

性及耐盐雾性能均显著优于 S-PU 涂料。

另外,本论文还制备了 P-FPU 涂料。由涂膜的表面性能、耐水性和耐盐雾性

能的表征说明随着 FPO 的摩尔平均质量降低,分子链变短,含氟侧链迁移的运动

位阻减小,表面氟含量更高,其制备的 P-FPU 涂膜的表面性能、耐水性、耐盐雾

性能明显提高;P-FPU 涂膜的耐蚀性能均优于相似结构的热塑性聚氨酯(以下简

称P-PU)涂料。S-FPU 与P-FPU 涂膜的耐水性和耐盐雾性比较表明,S-FPU 比

P-FPU 涂膜具有更加优异的耐腐蚀性能。

关键词:热固性含氟聚氨酯 结构控制 表面性能 热固性含氟聚氨

酯涂料 疏水性 耐盐雾性

ABSTRACT

In this thesis, homemade fluorinated polyether polyol (FPO), diphenyl

diisocyanate (MDI) and triethanolamine which acts as a crosslinking agent were used

to synthesize fluorinated thermosetting polyurethane (referred as S-FPU). On the basis

of determining the chemical structure of S-FPU, the S-FPU gelation time was

measured by rotational rheometer. By comparing with thermoset polyurethane

(referred as S-PU), S-FPU gel time is shorter than S-PU at the same curing temperature.

Three-dimensional network structure of the cured product was analyzed to show that

the crosslinking density of S-FPU is higher than the S-PU under the same conditions.

This indicates that F has promoted the reticulate structure formation of S-FPU.

Furthermore, in order to establish the relationship between surface structure and

surface properties, X-ray photoelectron spectroscopy (XPS) and Ar ion etching

techniques were combined to investigate the curing temperature, the ratio of raw

materials, the structure of FPO, and hard segment content to achieve a surface

migration and enrichment of fluorinated side chains. Reduce the S-FPU curing

temperature, S-FPU crosslink density and the fluorine-containing side chain moving

hindered are good for the fluorinated side chains to migrate and enrich to the surface of

S-FPU, which can make the larger surface contact angle and stronger hydrophobic.

And we evaluated the thermal stability of S-FPU 、S-PU and thermoplastic

FPU(referred as P-FPU), which can make a conclusion that the larger density of

fluorinated side chain, the higher hard segment content, the thermal stability of S-FPU

is better than the S-PU, the P-FPU.

On the basis of the surface structure control study of the S-FPU, we have prepared

S-FPU coating based on the guidance of the principle of anti-corrosion coating

formulation, which includes anticorrosive pigments, FPO, MDI, the

environment-friendly mixed solvents. According to the national standard of the

coating’s surface properties, water resistance and salt spray test were evaluated to

demonstrate the relationship between the surface properties and the surface fluorine

content, that is, the higher surface fluorine content, the better water resistance,

hydrophobicity and corrosion resistance of the S-FPU coating, and also its’ salt spray

resistance were significantly better than the S-PU coatings.

In addition, this paper has also prepared P-FPU paints . The Surface property,

water resistance and salt spray resistance of the films analyses indicated that since FPO

average molar mass decreases, the molecular chain is shortened, the migrated hindered

of the fluorinated side chain was reduced either, the surface fluorine had the tendency

to enrich to the film-air interface,so the preparation of the surface properties, water

resistance, salt spray performance of P-FPU coating had improved significantly; Of

course, the corrosion resistance of the P-FPU films was superior to similar structured

thermoplastic polyurethane (referred as P-PU) coating.

Key Words: Thermosetting fluorinated polyurethane, Structure

control, Surface properties, Thermosetting

Fluorinated polyurethane coating, Hydrophobicity,

Anti-corrosion.

目录

摘要

ABSTRACT

第一章 绪论 ····················································································· 1

1.1 含氟聚合物简介 ······································································· 1

1.2 含氟聚氨酯的结构与性能 ·························································· 4

1.3 含氟树脂涂料的研究现状 ·························································· 6

1.4 本论文的研究内容 ·································································· 11

1.5 本论文的特色与创新性 ···························································· 12

第二章 实验部分 ·············································································· 13

2.1 主要试剂 ·············································································· 13

2.2 实验主要仪器与设备 ······························································· 14

2.3 原料合成及表征 ····································································· 14

2.3.1 S-FPU 的原料合成 ··························································· 14

2.3.2 S-FPU 合成原料的表征 ····················································· 16

2.4 S-FPU 的合成及其 FPU 涂料的制备 ············································· 18

2.4.1 S-FPU 的合成·································································· 18

2.4.2 FPU 涂料的制备 ······························································ 18

2.5 FPU 及其涂料的性能测试 ·························································· 21

2.5.1 S-FPU 结构分析 ······························································ 21

2.5.2 FPU 性能表征 ································································· 22

2.5.3 FPU 涂料性能评价 ··························································· 23

2.6 FPU 命名规则 ········································································· 23

第三章 结果与讨论 ··········································································· 24

3.1 含氟化合物的合成与结构分析 ··················································· 24

3.1.1 FO 的合成及结构分析 ······················································· 24

3.1.2 FPO 的合成与分析 ··························································· 25

3.2 S-FPU 的合成及结构分析 ·························································· 27

3.2.1 S-FPU 的化学结构表征 ····················································· 27

3.2.2 S-FPU凝胶化时间的测定 ·················································· 28

3.2.3 S-FPU 交联密度的测定 ····················································· 30

3.3 反应条件对 S-FPU 表面结构的影响 ············································ 31

3.3.1 FPO 结构对 S-FPU 表面 F含量的影响 ·································· 32

3.3.2 硬段含量对 S-FPU 表面 F含量的影响·································· 34

3.3.3 固化温度对含氟侧链迁移能力的影响 ·································· 36

3.4 S-FPU 表面特性的研究 ····························································· 38

3.4.1 FPO 结构对 S-FPU 表面疏水性能的影响 ······························· 39

3.4.2 硬段含量与 S-FPU 表面疏水性能的关系 ······························· 40

3.4.3 固化温度对 S-FPU 表面疏水性的影响 ·································· 40

3.5 热稳定性研究 ········································································ 41

3.5.1 S-FPU 结构对其热稳定性影响 ············································ 41

3.5.2 S-FPU 与P-FPU 热稳定性的比较 ········································· 44

3.5.3 S-FPU 和S-PU 的热稳定性 ················································ 45

3.6 FPU 涂料的制备及性能表征 ······················································· 46

3.6.1 FPU 涂料配方指导原则 ····················································· 46

3.6.2 S-FPU涂料的制备及性能表征 ············································ 47

3.6.3 P-FPU 涂料的制备及性能表征 ············································ 50

3.6.4 FPU 与PU 涂膜性能比较 ··················································· 53

第四章 结论 ··················································································· 56

参考文献 ························································································· 57

在读期间公开发表的论文和承担科研项目及取得成果 ······························· 63

致 谢 ···························································································· 64

第一章 绪论

1

第一章 绪论

在地壳中,氟的含量为约 0.015%,主要是存在一些难溶的化合物中,如萤石

(CaF2),冰晶石(Na3AlF6)和氟磷灰石(Ca5F(PO4)3)等。被称为“化学界顽童”

的氟元素是一种反应性能特别高的元素,其一旦与其它元素相结合,就会变成一

种难以被药品和溶剂腐蚀的化合物,同样该化合物还具有耐热性的高度安全性能。

类似地,当聚合物的一部分或全部的氢原子被氟原子取代后,取代后的聚合物会

产生很多其它聚合物无可比拟的优越的性能,这种聚合物就是含氟聚合物,若聚

合物中的 C-F 键取代所有的 C-H 键,则称为全氟聚合物[1,2]。

1.1 含氟聚合物简介

1934 年德国赫斯特公司发现聚三氟氯乙烯,1938 年美国陶氏化学公司合成

PTFE,自此以后对高分子含氟聚合物的研究至今已有近 70 年的历史。1946 年杜

邦公司将聚四氟乙烯商品化后,高分子含氟聚合物材料的开发已经经历热熔型、

溶剂可溶型和可交联型的几个阶段[3]。含氟聚合物材料的优异性能,如优良的耐

热性,耐化学品性,不粘性,耐候性,低摩擦系数和介电常数等,吸引了人们的

目光,含氟聚合物也获得了长远的发展。

早期的含氟聚合物的主要代表是氟单体均聚物,如: FTFE,PCTFE,PVDF,

PVF 等,即所谓的第一代含氟聚合物。这类热塑性含氟聚合物一方面具有规整的

结构,其本身呈现半结晶态,所以具有优良的耐溶剂性,另一方面其优异的耐溶

剂性使得其在溶剂中难以溶解[4],这对加工和使用造成不便。所以刚开始的氟碳

涂料只可以制成水分散性涂料,粉末涂料或有机溶胶,但这些涂层均需要高温烘

烤才可以成膜。第二代含氟聚合物是基于氟烯烃的共聚物,如 VDF/CTFE,VDF/

HFP,FEP,PFA,ETFE,E/CTFE 等。非氟单体引入后,含氟共聚物的结晶性能

会降低,从而烘烤温度降低,提高了含氟聚合物在溶剂中的溶解性。第三代氟碳

树脂,如氟乙烯,羟基烃基乙烯基醚共聚物(FEVE)等,此类含氟树脂中含有-OH

和-COOH,此类树脂是可以在室温下与异氰酸酯或氨基树脂交联固化[5]。含氟聚

合物的发展历史[3]可见表 1.1。

表1.1 含氟聚合物的发展历史

时间

产品品种

1934-1938

1950

聚三氟氯乙烯、聚四氟乙烯

聚偏氟乙烯、聚氟乙烯、聚三氟乙烯

相关推荐

-

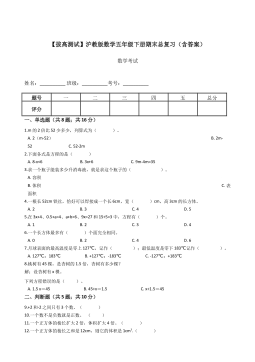

【拔高测试】沪教版数学五年级下册期末总复习(含答案)VIP免费

2024-11-19 13

2024-11-19 13 -

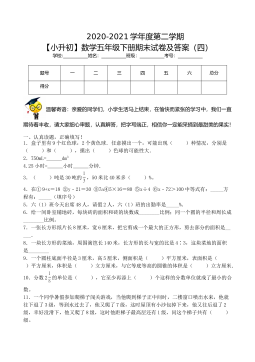

【基础卷】小学数学五年级下册期末小升初试卷四(沪教版,含答案)VIP免费

2024-11-19 8

2024-11-19 8 -

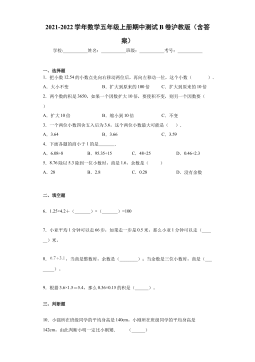

期中测试B卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 8

2024-11-19 8 -

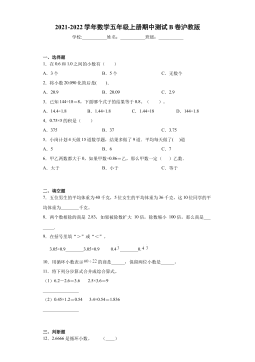

期中测试B卷(试题)- 2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 10

2024-11-19 10 -

期中测试A卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 14

2024-11-19 14 -

期中测试A卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 15

2024-11-19 15 -

期中测B试卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 11

2024-11-19 11 -

期中测A试卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 22

2024-11-19 22 -

【七大类型简便计算狂刷题】四下数学+答案

2025-03-18 6

2025-03-18 6 -

【课内金句仿写每日一练】四下语文

2025-03-18 6

2025-03-18 6

作者:侯斌

分类:高等教育资料

价格:15积分

属性:67 页

大小:3.39MB

格式:PDF

时间:2025-01-09

相关内容

-

期中测试A卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

期中测B试卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

期中测A试卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

【七大类型简便计算狂刷题】四下数学+答案

分类:中小学教育资料

时间:2025-03-18

标签:数学计算;校内数学

格式:PDF

价格:1 积分

-

【课内金句仿写每日一练】四下语文

分类:中小学教育资料

时间:2025-03-18

标签:无

格式:PDF

价格:1 积分