钢护筒混凝土灌注桩基础抗震承载性能研究

VIP免费

摘 要

我国大型桥梁中常采用的高桩承台基础通常是地震作用下的薄弱环节,利用

钢护筒参与桩身受力来改善基础的抗震性能,具有高效、简单且又经济的突出特

点。但由于目前尚缺乏具有针对性的理论与试验研究,对钢护筒混凝土灌注桩的

抗震机理尚不清楚,导致了在分析方法以及构造处理上的不统一。本文主要针对

考虑钢护筒效应的桩身承载特性,以及钢护筒与承台不同连接构造形式的抗震性

能等两个方面开展研究。主要研究成果有:

(1) 室内试验针对桩身有粘结和无粘结两种不同工况,桩头节点浅嵌入、锚

筋嵌入和深浅入三种不同工况分别进行试验研究,利用 ABAQUS 软件建立数值

模型,进行验证分析,符合性较好。

(2) 钢护筒-桩身极限承载能力受界面粘结削弱的影响效应相对较小,可以简

化采用钢管混凝土组合截面进行计算,再偏于安全地考虑不小于 0.85的折减系数。

(3) 钢护筒-承台连接节点的承载能力受节点连接形式的影响很大,对不满足

平截面假定的桩头节点形式,承载力计算困难,可以由在平截面假定下计算的抗

弯承载力乘以一个增大系数作为其设计和研究的依据,但增大系数不大于 1.16。

关键词: 高桩承台 钻孔灌注桩 钢护筒 抗震性能 设计方法

ABSTRACT

Pile foundation with high bent cap, as a very popular foundation type used for

many major bridges in China, are actually the most vulnerable component under

seismic actions. Making steel casings participate foundation load bearing to enhanced

its seismic resistance is considered to be a very promising measure for this problem

since it can benefit a lot in construction convenience and also in cost saving. However,

the interaction mechanics between the steel casing and concrete pile is still unclear

because of the lack of special theoretical and experimental researches, and this has

result in disaccord in theoretical hypothesis, analysis models and structural

constructions.This work mainly focus on the bearing characteristics of piles with the

steel tube and seismic performance capacity of joints between steel casing and cushion

cap with various configuration. The main achievements and conclusions are as follows:

(1) Laboratory tests on piles with bonded and unbonded in two different

conditions,and the node of pile head in three different conditions were studied.

Numerical model is established by using ABAQUS software, The analysis results

agreed well.

(2) The reduction of the bending capacity due to the weak bonding property is no

more than 15 percent. Therefore, it can be simply evaluated by the ideal composite

section method with an additional discount coefficient no less than 0.85.

(3) The bearing capacity of the pile-cap joint is greatly influenced by the

connection manner. The node of pile head unsatisfied with the assumption of plane

cross section is difficult to calculate the bearing capacity, may be calculated in the

assumption of plane section of the bending bearing capacity with an increasing

coefficient , as the basis of design and research .But the increasing coefficient is less

than 1.16.

Key words: high-rise pile cap foundation, cast in place pile, steel shell,

seismic performance, designing method

目录

中文摘要

ABSTARCT

第一章 绪 论 .................................................................................................................. 1

1.1 研究背景 ............................................................................................................ 1

1.2 研究现状 ............................................................................................................ 3

1.2.1 桩身的研究现状 ...................................................................................... 3

1.2.2 桩头节点的研究现状 .............................................................................. 4

1.3 存在问题 ............................................................................................................ 5

1.4 研究内容及安排 ................................................................................................ 6

第二章 钢护筒混凝土灌注桩桩身拟静力试验 ............................................................ 7

2.1 实验目的 ............................................................................................................ 7

2.2 实验方法的选择 ................................................................................................ 7

2.3 试验模型设计 .................................................................................................... 7

2.4 试验加载设备与试件安装 ................................................................................ 9

2.4.1 加载设备的选择 ...................................................................................... 9

2.4.2 试架安装 ................................................................................................ 10

2.5 加载制度 .......................................................................................................... 10

2.6 实验观测 ........................................................................................................... 11

2.7 材性试验 ........................................................................................................... 11

2.8 试验现象与破坏状态 ...................................................................................... 13

2.9 实验结果与分析 .............................................................................................. 14

2.9.1 滞回曲线 ................................................................................................ 14

2.9.2 骨架曲线 ................................................................................................ 17

2.9.3 刚度退化 ................................................................................................ 18

2.9.4 延性系数 ................................................................................................ 20

2.9.5 耗能性能 ................................................................................................ 21

2.10 本章小结 ........................................................................................................ 22

第三章 桩身抗弯承载力模拟分析与简化估算 .......................................................... 23

3.1 有限元模型的建立 .......................................................................................... 23

3.1.1 基本构型 ................................................................................................ 23

3.1.2 材料本构 ................................................................................................ 24

3.1.3 粘结界面 ................................................................................................ 28

3.2 数值模型验证与粘结强度影响分析 .............................................................. 29

3.2.1 数值模型验证 ........................................................................................ 29

3.2.2 粘结强度影响分析 ................................................................................ 30

3.2.3 并联构件刚度分配计算方法适用性分析 ............................................ 32

3.2.4 桩身粘结强度对中和轴位置的影响 .................................................... 33

3.3 简化估算方法 .................................................................................................. 34

3.3.1 钢管混凝土计算理论 ............................................................................ 34

3.3.2 等效折减系数 ........................................................................................ 36

3.4 本章小结 .......................................................................................................... 39

第四章 桩头节点拟静力试验 ...................................................................................... 40

4.1 试验目的 .......................................................................................................... 40

4.2 试验方法的选择 .............................................................................................. 40

4.3 模型设计 .......................................................................................................... 40

4.4 实验仪器与安装 .............................................................................................. 42

4.5 加载制度 .......................................................................................................... 43

4.6 试验现象现象与破坏状态 .............................................................................. 43

4.7 实验结果与分析 .............................................................................................. 45

4.7.1 滞回曲线 ................................................................................................ 45

4.7.2 骨架曲线 ................................................................................................ 49

4.7.3 刚度退化 ................................................................................................ 50

4.7.4 延性系数 ................................................................................................ 51

4.7.5 耗能性能 ................................................................................................ 52

4.8 本章小结 .......................................................................................................... 52

第五章 桩头抗弯承载力模拟分析与简化估算 .......................................................... 54

5.1 有限元模型的建立 .......................................................................................... 54

5.1.1 模拟方法的选取 .................................................................................... 54

5.1.2 模型建立 ................................................................................................ 55

5.2 模拟验证与分析 .............................................................................................. 55

5.2.1 破坏状态对比分析 ................................................................................ 56

5.2.2 钢护筒沿 Z轴应力分布的对比分析 .................................................... 57

5.2.3 承载力的对比分析 ................................................................................ 58

5.3 锚筋含量影响分析 .......................................................................................... 60

5.4 简化估算 .......................................................................................................... 61

5.4.1 UCFYBER 软件简介 .............................................................................. 61

5.4.2 分析模型 ................................................................................................ 62

5.4.3 浅嵌入式承载力的简化估算 ................................................................ 62

5.4.4 锚筋嵌入式承载力的简化估算 ............................................................ 63

5.5 本章小结 .......................................................................................................... 64

第六章 结论与展望 ...................................................................................................... 66

6.1 结论 .................................................................................................................. 66

6.2 进一步工作方向 .............................................................................................. 67

参考文献 ........................................................................................................................ 68

在读期间公开发表的论文和承担科研项目及取得成果 ............................................ 71

致 谢 .............................................................................................................................. 72

第一章 绪论

1

第一章 绪 论

1.1 研究背景

近十多年来,随着国内经济的快速发展,我国桥梁建设也进入了最辉煌的发

展时期,截至目前,我国大陆已建成千米以上大跨度桥梁已经有数十座之多。值

得注意的是,美国、欧洲以及日本等的大跨度桥梁较多采用沉箱基础,而我国绝

大多数采用钻孔灌注桩群桩基础,其中在深水场地下又多为高桩承台结构形式,

形成了我国大跨度桥梁基础类型独特而鲜明的特点,如表 1.1 所示[1-3],这充分显

示出钢护筒混凝土灌注桩在国内大跨度桥梁基础建设中应用的广泛性。

表1.1 国内外典型大跨度桥梁基础

桥梁名称

国别

主跨

基础类型描述

苏通长江大桥

中国

1088m

南北塔均为高桩承台,桩径2.8/2.5m 变截面

昂船洲大桥

香港

1018m

低桩承台基础,桩径2.8m

Rion-Antirion Bridge

希腊

3×560m

减隔震基础

鄂东长江大桥

中国

926m

南塔低桩承台,桩径2.5m;北塔高桩承台,桩径2.8/2.5m 变截

面

Normandy Bridge

法国

856m

低桩承台,桩径2.1m

荆岳长江大桥

中国

816m

南塔低桩承台,桩径2.2m;北塔高桩承台,桩径3.0m

东海大桥(颗珠山)

中国

420m

南北塔均为高桩承台,桩径2.5m

杭州湾大桥(北航道)

中国

448m

南北塔均为高桩承台,桩径3/2.5m 变截面

Akashi Kaikyo Bridge

日本

1991m

沉箱基础

西堠门大桥

中国

1650m

低桩承台,桩径2.8m

Great belt Bridge

丹麦

1624m

沉箱基础

润扬长江大桥

中国

1490m

南塔低桩承台,桩径2.8m;北塔高桩承台,桩径2.8m

南京长江四桥

中国

1560m

南北塔为高桩承台,南塔桩径3.2/2.8m 变截面,北塔桩径2.8m

Tataro Bridge

日本

890m

沉箱基础

江阴长江大桥

中国

1385m

感潮河段,低桩基础,桩径3m

青马大桥

香港

1377m

沉箱基础

Gold Gate Bridge

美国

1280.2m

沉箱基础

响礁门大桥

中国

951m

高桩承台,桩径2.5m

Verrazano Bridge

美国

1298.5

沉箱基础

Humber Bridge

英国

1410m

北塔为混凝土阀式基础,南塔为沉箱基础

上海理工大学硕士学位论文

2

许多大跨度桥梁的结构抗震性能研究表明:高桩承台基础由于承台体量巨大,

在地震作用下会产生很大的水平惯性力,并且承台与上部结构之间还会产生明显

的高模态动力耦合效应,再加上深水区的桥梁基础自由段桩身又缺乏土体侧向支

撑作用,致使基础部分往往成为结构在地震作用下的首要薄弱环节[4-5]。以苏通大

桥为例,钢箱梁重约 4.9 万吨,两个桥塔总重约 14.3 万吨、两个承台总重则高达

30 余万吨,约合桥塔与钢箱梁总重的 1.6 倍。抗震分析结果表明,桩基中 80%的

水平地震力由承台惯性力产生[6]。尽管高桩承台基础较长的桩身自由段可以提高

基础的柔度,并可能使整个承台底的水平地震力有所下降,但较长的桩身自由段

同时也导致了较大的单桩桩身弯矩。如图 1.1 所示,一般情况下,高桩承台基础

的单桩最大弯矩位于桩顶与承台的节点处或入土 1~3倍桩径处[7-9]。目前我国大

跨度桥梁中的高桩承台基础,由于建成时间尚短而未经历真正的强震检验,但与

之相类似的高桩码头在历次强震中,最常见的震害即为发生在桩顶处的节点破坏

或入土 1~3倍桩径处的桩身弯曲破坏[10-13]。

(a)

(b)

(c)

(d)

图1.1 不同自由桩长下的单桩地震弯矩分布对比

第一章 绪论

3

高桩承台基础的钻孔灌注桩一般都需要沉放钢护筒来辅助施工,但在施工完

成后又难以拔出再利用。由于钢护筒的实际埋置区段与桩身地震响应较大的区段

非常接近,因此,若能充分利用钢护筒的强度和延性来参与混凝土灌注桩的桩身

受力,形成钢护筒-混凝土灌注桩组合基础,进而提升整个基础的抗震性能,将不

失为一个经济、简便、而又有效的解决方案,符合我国大跨度桥梁基础的现状和

特点,具有广泛的应用前景。

1.2 研究现状

1.2.1 桩身的研究现状

目前,针对钢护筒-混凝土灌注桩抗震性能的相关研究还非常少,尤其是缺乏

基础性试验研究的报道,对其共同承载机理以及结构抗震性能尚缺乏明确的研究

结论。但从结构构成上看,钢护筒-混凝土灌注桩与钢管混凝土桩之间存在很大的

相似性,因此,可以首先从钢管混凝土桩的相关研究成果中获得有益的启示。在

美国,自上世纪 80 年代,Priestley 等学者开展了有关钢管混凝土桩的抗震性能试

验研究,表明外套钢管可以显著提高混凝土桩的抗弯、抗剪以及约束延性等性能

[14]。近年来,出于对强地震区、软弱或液化场地中的桩基抗震设计与加固需求,

加州大学、密苏里大学、华盛顿大学、阿拉斯加交通部等相关高校和研究机构广

泛开展了对 CISS(cast-in-steel-shell-pile)的抗震性能研究。其中,比较具有代表

性的研究包括:Seible 等人根据群桩基础在地震作用下的内力响应特点,进行了

CISS 桩在压弯、反向拉弯往复作用下的试验研究,指出 CISS 桩的破坏一般由拉

弯状态控制[15-16];Gebman 等人研究了 CISS 桩的轴向荷载传递机理[17];Manzari

等人在此基础上进行了 CISS 群桩基础的非线性推倒分析[18];Ashford 等人则研究

了CISS 桩用于抵抗不同土层之间的相对错动以及液化土的侧向流动等[19]。在日

本,1992 年Nippon Steel 针对宫城县地震后混凝土桩的震害问题,开发了 SKTB

钢管混凝土灌注桩(又称耐震桩)[20]。该灌注桩的突出特点是混凝土桩基的外套

钢管由带肋钢板卷焊而成,因此极大地改善了混凝土与管壁之间的粘结咬合作用,

可以有效地防止两者之间的滑移。该 SKTB 桩在 1995 年神户地震中极少发生破

坏,表现出了非常优越的抗震性能,目前 SKTB 桩在日本已申请了多项技术专利

[21-22]。此外,日本的大芝桥也采用了带凸肋的线形钢护筒[23] ,使钢护筒本身与

填充的核心钢筋混凝土确保整体受力作用。由于欧美以及日本等国的大跨度桥梁

较多采用沉箱基础,而钢护筒混凝土灌注桩的应用相对较少,所以直接针对钢护

筒混凝土灌注桩的承载机理的研究报道还很少。

国内的部分学者也对钢管混凝土结构用于强震地区的基础工程进行了相关研

究[24-25]。部分学者还直接针对钢护筒混凝土灌注桩的承载特性做了研究。汪承志[26]

相关推荐

-

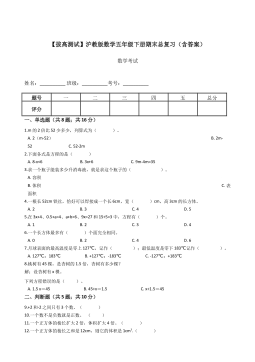

【拔高测试】沪教版数学五年级下册期末总复习(含答案)VIP免费

2024-11-19 20

2024-11-19 20 -

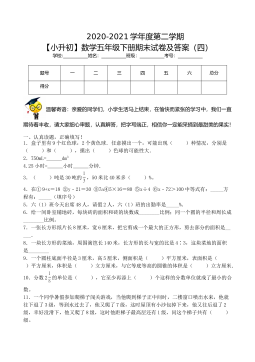

【基础卷】小学数学五年级下册期末小升初试卷四(沪教版,含答案)VIP免费

2024-11-19 10

2024-11-19 10 -

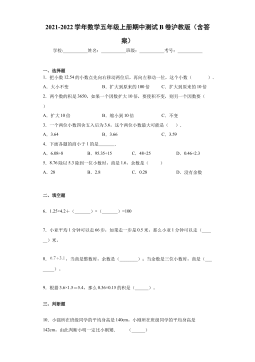

期中测试B卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 12

2024-11-19 12 -

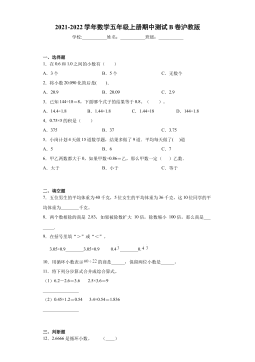

期中测试B卷(试题)- 2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 18

2024-11-19 18 -

期中测试A卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 19

2024-11-19 19 -

期中测试A卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 26

2024-11-19 26 -

期中测B试卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 25

2024-11-19 25 -

期中测A试卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 32

2024-11-19 32 -

【七大类型简便计算狂刷题】四下数学+答案

2025-03-18 16

2025-03-18 16 -

【课内金句仿写每日一练】四下语文

2025-03-18 43

2025-03-18 43

作者:侯斌

分类:高等教育资料

价格:15积分

属性:75 页

大小:3.61MB

格式:PDF

时间:2025-01-09

相关内容

-

期中测试A卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

期中测B试卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

期中测A试卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

【七大类型简便计算狂刷题】四下数学+答案

分类:中小学教育资料

时间:2025-03-18

标签:数学计算;校内数学

格式:PDF

价格:1 积分

-

【课内金句仿写每日一练】四下语文

分类:中小学教育资料

时间:2025-03-18

标签:无

格式:PDF

价格:1 积分