沸石填充电极电解法去除水中氨氮的研究

VIP免费

摘 要

近几十年,随着工业的发展、人口的激增,我国在实现经济腾飞的过程中,

也对环境造成了严重的污染,尤其是氮、磷等营养元素的肆意排放,对我国的湖

泊、河流和海洋造成了严重的富营养化,水华、赤潮等现象频发,不但污染了宝

贵的水资源,而且严重威胁水生生物及人类的健康。因此,要改善目前氨氮污染

的现状,需要严格控制氨氮的排放,降低水体中的氨氮含量。目前,应用于工程

中的氨氮处理方法很多,如生物法、离子交换法、折点氯化法、吹脱法等,各种

方法都有自己的优缺点及适用范围。

本研究结合了沸石去除氨氮和电化学氧化法对氨氮的氧化性,以及电化学氧

化可对沸石进行再生的特点,自制了沸石填充电极反应器并应用其去除水中氨氮,

期望开发一种快速深度去除氨氮的方法。探讨了沸石填充电极反应器降解氨氮的

机理,并对其在间歇流及连续流条件下的影响因素进行了研究,确定了反应器去

除氨氮的最佳实验条件,及处理实际生活污水的效果。另外,利用 SEM、XRD、

N2吸附脱附等材料表征技术,对天然沸石及电解后的沸石进行了材料表征,探讨

了电化学氧化过程对沸石的比表面积、孔径分布、晶体结构等的影响,并对沸石

吸附氨氮的动力学模型进行了分析。获得的结论如下:

从氨氮在 Pt 电极上的循环伏安图可以看出,在电极表面发生氧化反应的主要

为分子态氨氮,氨氮电化学氧化过程受 pH 值影响较大,此外氨氮的初始浓度、扫

描面积及扫描速度也对氨氮的电化学氧化过程产生影响。钛基 RuO2电极对氨氮的

催化活性较低,氨氮的氧化峰较小且其受氨氮初始浓度及溶液 pH 影响较小,扫

描面积及扫描速度与电化学氧化过程中的电流呈正比,但对氨氮氧化峰的电位及

大小无影响。因此要加强电化学处理氨氮的直接氧化作用,需要选择对氨氮选择

性强的电极材料。

在间歇流条件下使用沸石填充电极反应器处理氨氮时,通过对电解过程中反

应体系内含氮物质的测定,分析了此反应器降解氨氮的机理,证实了反应器去除

氨氮的机理主要为沸石离子交换和电化学氧化共同作用的结果。体系中存在 Cl时,

Cl通过电化学氧化作用生成具有强氧化性作用的 HClO 和ClO,一方面 HClO 和

ClO可将氨氮氧化为氮气,实验结果证实约有 82%的氨氮被氧化为氮气,未能被

氧化为 N2的氨氮一部分生成了 NO3及NO2,另一部分存在于氯胺(NH2Cl、NHCl2

和NCl3)中;另一方面 HClO 和ClO又可将吸附了氨氮的沸石进行再生,使沸石

一直处于快速吸附氨氮的阶段,因此也提高了沸石填充电极反应器处理氨氮的效

率。氨氮的去除速率受氨氮初始浓度和电流密度影响较大,溶液的 pH 值和 Cl―浓

度的变化对氨氮的去除效果影响较小。总体来看,在间歇流条件下沸石填充电极

反应器对氨氮的处理效率优于传统的二维电极,因此沸石填充电极反应器是对氨

氮进一步处理的有效途径和方法。另外,应用沸石填充电极反应器处理实际生活

污水的结果表明,反应器对污水中的氨氮有较好的处理效果,电解 1.5 h 后,实际

废水中的氨氮浓度从 27.8 mg N/L 降到 0.5 mg N/L,满足国家城镇污水排放一级 A

标准要求。

在连续流条件下,沸石填充电极反应器处理氨氮废水受水力停留时间(HRT)、

电流密度、Cl浓度及氨氮初始浓度的影响较大。当进水氨氮浓度为 25 mg N/L 时,

在Cl浓度为 300 mg/L、电流密度为 13.7 mA/cm2、HRT 为30 min 的条件下(此为

各条件的参考量),电解 1.5 h 后出水氨氮浓度达到并稳定维持在小于 1 mg N/L 的

水平,并 可使反应器内预饱和的沸石得到再生。为使浓度为 25 mg N/L 的氨氮全部

去除,保持其他变量为参考量的值,最小需要 HRT 为10 min、Cl浓度为 210 mg/L、

电流密度为 7.6 mA/cm2。对于高浓度氨氮废水,在 HRT 为30 min 条件下,出水氨

氮浓度达到稳定时,50 mg N/L 和90 mg N/L 的模拟氨氮废水的去除率分别为 74%

和38%。所以,要提高高浓度氨氮废水的去除率,需要相应的增加其 HRT。应用

沸石填充电极反应器在连续流条件下处理实际生活污水,维持电流密度为13.7

mA/cm2,Cl浓度为 300 mg/L 时,处理氨氮浓度为 13.5、30.2、53.5 mg N/L 的废

水,最低需要将 HRT 维持在 7.5、11 和21 min.

应用 SEM、XRD、N2吸附脱附等材料表征手段对电解前后沸石进行了表征,

BET 的结果显示,电解后沸石的比表面积和孔隙容量相比于天然沸石大大增加,

孔径分布与天然沸石相比趋于均一化。XRD 数据显示,电解过程并未对沸石的晶

体结构造成较大的改变,这也与 SEM 图片所示电解前后沸石均为板状的结构相符。

但是电解后沸石表面变的粗糙,由此可能造成了沸石比表面积和孔隙容量的增加。

虽然沸石电解前后的比表面积及孔隙容量大大增加,但沸石的吸附容量并没有较

大的改变,进一步论证了沸石主要通过离子交换作用去除氨氮。另外,天然沸石

和电解后沸石在不同氨氮浓度下,对不同的吸附动力学模型的拟合情况可以看出,

沸石吸附氨氮的实验结果可以较好的拟合一级动力学模型、二级动力学模型和

Bangham 模型。沸石的颗粒内扩散模型说明,天然沸石对氨氮的吸附过程主要受

内扩散的控制,而电解后的沸石主要由溶液扩散控制。

关键词:电化学氧化 氨氮 循环伏安法 沸石表征 吸附动力学模型 污

水处理

ABSTRACT

With the development of industry, the improvement of economy and the surging

population, environmental pollution is getting more and more serious. Uncontrolled

releasing of nutrient elements, like nitrogen and phosphorous, lead to extensive

eutrophication for lakes, rivers and oceans. The phenomenon of algal blooming and red

tides happened frequently during these years which not only damage the precious

natural water resource, but also threaten the safety of aquatic life and human. Thus it is

very important and necessary to control the discharge of ammonia. There are many

applicable methods used to remove ammonia at present, like biological nitrification

/de-nitrification, ion-exchange, break-point chlorination method, air striping and so on.

But each method has its advantages and disadvantages.

In this experiment, zeolite-packed electrolysis reactor was made to quickly and

deeply remove of ammonia which was combined the function of ion exchange,

electrochemical oxidation and its regenerate effect for saturated zeolite. The mechanism

and influence factors for the removal of ammonia under batch and continuous mode

were studied. The optimum condition and the performance in treating actual municipal

sewage were identified. In addition, the characterization of the packed zeolite before

and after electrolysis was confirmed with the assistance of materials characterization

techniques like SEM, BET and N2 adsorption/desorption etc. The impact of

electrochemical oxidation process for zeolite was studied in the aspect of specific

surface area, pore size distribution, crystalline structure and so on. Ammonia removal

kinetic model by the adsorption was also studied. Conclusions were obtained as

followings:

Cyclic voltammetry of ammonia on Pt electrode showed that it is molecular

ammonia in the solution oxidized to nitrogen gas rather than ammonium ions. Then the

direct oxidation of ammonia on electrode is significant influenced by the value of pH. In

addition, initial ammonia concentration, scanning area and scanning rate are also

showed a great impact for ammonia’s direct oxidation. However Ti/ RuO2 electrode has

a low catalytic activity for ammonia. Ammonia oxidation peak is very low and not

influenced by pH and ammonia concentration. But scanning area and scanning rate are

proportionate to the current of ammonia oxidation peak. Then in order to enhance the

direct oxidation of ammonia, specific electrode material must be chosen.

Through monitoring and measurement of nitrogen substances in the electrolytic

system, the mechanism of ammonia removal in the zeolite packed electrolysis reactor

was analyzed which is the combination of ion-exchange and electrochemical oxidation.

Strong oxidizing substances, HClO and ClO, are produced during electrolysis with the

existence of chloride ions. Those substances not only could degrade ammonia to

nitrogen gas, but also could regenerate saturated zeolite. This process make sure that

zeolite are always maintaining in the phase of rapid adsorption and ensure the zeolite

packed electrolysis reactor has big advantages over conventional two dimensional

electrode reactor. The results showed that nearly 82% ammonia were oxidized to N2,

other may be changed into NO3, NO2, chloramine (including NH2Cl、NHCl2 and

NCl3), etc. In addition, Ammonia removal rate was significantly affected by initial

ammonia concentration and current density when using zeolite packed electrolysis

reactor to remove ammonia under circulating flow mode. But pH and Cl concentration

perform little effect. Generally speaking, the performance of zeolite-packed electrolysis

reactor is better than the traditional two dimensional electrode reactor. It is an effective

method for further removal of ammonia. This reactor also performs a good result when

using it to treat actual municipal sewage. After electrolysis for 1.5 h, the ammonia

concentration decreased from 27.8 mg N/L to 0.5 mg N/L which met the standard of

The First Grade of Environment Quantity Standards for surface water in China.

HRT, current density, Cl concentration and initial ammonia concentration have a

significant effect for ammonia removal by zeolite packed electrolysis reactor under

continuous mode. Under the condition of 300 mg/L chloride ion concentration, 13.7

mA/cm2 current density and 30 min HRT, the ammonia concentration decreased from

25 mg N/L to 0.3 mg N/L within 1.5 h electrolysis time and the pre-saturated zeolite

could be regenerated. Make sure other conditions were fixed, a minimum of 10 min

HRT, 210 mg/L chloride ion concentration, 7.6 mA/cm2 current density were required to

nearly remove totally 25 mg N/L ammonia. But for high ammonia concentration, like 50

mg N/L and 90 mg N/L, ammonia removal rate were 74% and 38% respectively within

30 mim HRT. HRT must be increased to make sure specific ammonia removal rate when

ammonia concentration is high. For the treatment of municipal wastewater, minimum

HRT of 7.5, 11 and 21 min were suggested for initial ammonia concentrations of 13.5,

30.2 and 53.5 mg N/L under condition of 300 mg/L chloride ion concentration, 13.7

mA/cm2 current density.

Moreover, SEM, XRD and N2 adsorption/desorption techniques were used to

characterize zeolites before and after electrolysis. The results of BET showed that the

specific surface area and pore volume of zeolite after electrolysis increased significantly

compared with natural one. And the distribution of pore size was narrowed after

electrolysis. Based on XRD data, zeolite’s main crystalline structure were not changed

after a long time of electrolysis which is accordance with the SEM micrographs.

However, the appearance of zeolite after electrolysis became rougher than the natural

one which may cause the increase of specific surface area and pore volume. On the

other hand, there is no significant change of ammonia adsorption capacity after

electrolysis which explains ammonia removed by zeolite through ion exchange rather

than physical adsorption. In addition, ammonia removal by zeolites have a good fitting

with pseudo-first order kinetic model, pseudo-second order kinetic model and Bangham

model for both before and after electrolysis. Based on particle diffusion model, internal

diffusion is the controlling step for natural zeolite and solution diffusion is the

controlling step for zeolite after electrolysis.

Key Word: electrochemical oxidation, ammonia, cyclic voltammetry,

zeolite characterization, adsorption kinetics, wastewater treatment

目录

中文摘要

ABSTRACT

第一章 绪论 ................................................................................................................ 1

1.1 课题的背景及意义 ........................................................................................... 1

1.2 氨氮处理方法及研究现状 ............................................................................... 1

1.2.1 氨氮的来源及危害 ...................................................................................... 1

1.2.2 氨氮的处理方法 .......................................................................................... 3

1.3 电化学技术 ....................................................................................................... 7

1.3.1 电化学技术简介 .......................................................................................... 7

1.3.2 电化学法去除污染物的原理 ...................................................................... 8

1.3.3 影响电化学处理效果的因素 .................................................................... 10

1.3.4 三维电极的应用及研究现状 .................................................................... 12

1.3.5 电化学技术的发展趋势 ............................................................................ 14

1.4 选题意义及研究内容 ...................................................................................... 15

1.4.1 选题的意义 ................................................................................................ 15

1.4.2 研究内容 .................................................................................................... 15

第二章 实验材料及方法 .......................................................................................... 17

2.1 实验试剂与仪器 ............................................................................................. 17

2.2 实验流程及方法 ............................................................................................. 17

2.2.1 氨氮电化学氧化特征的研究 .................................................................... 17

2.2.2 间歇流条件下反应器处理氨氮的研究 .................................................... 18

2.2.3 连续流条件下反应器处理氨氮的研究 .................................................... 20

2.2.4 电解前后的沸石表征和吸附量的变化 .................................................... 21

2.3 分析方法 ......................................................................................................... 21

第三章 氨氮电化学氧化特征的研究 ...................................................................... 23

3.1 实验目的 ......................................................................................................... 23

3.2 实验结果与讨论 ............................................................................................. 23

3.2.1 氨氮在 Pt 电极表面的直接氧化过程及影响因素分析 ........................... 23

3.2.2 氨氮在 Ti/RuO2电极表面的直接氧化过程及影响因素分析 ................. 29

3.3 本章小结 ......................................................................................................... 32

第四章 间歇流条件下反应器处理氨氮的研究 ...................................................... 33

相关推荐

-

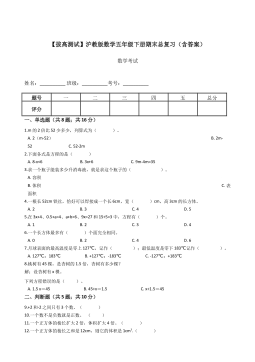

【拔高测试】沪教版数学五年级下册期末总复习(含答案)VIP免费

2024-11-19 13

2024-11-19 13 -

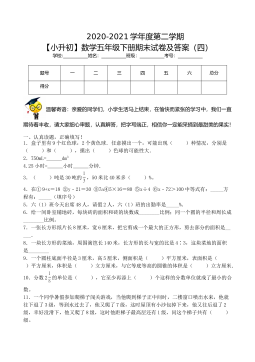

【基础卷】小学数学五年级下册期末小升初试卷四(沪教版,含答案)VIP免费

2024-11-19 8

2024-11-19 8 -

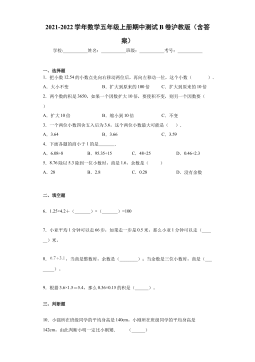

期中测试B卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 8

2024-11-19 8 -

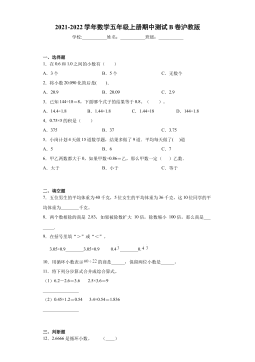

期中测试B卷(试题)- 2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 10

2024-11-19 10 -

期中测试A卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 14

2024-11-19 14 -

期中测试A卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 15

2024-11-19 15 -

期中测B试卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)VIP免费

2024-11-19 11

2024-11-19 11 -

期中测A试卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)VIP免费

2024-11-19 22

2024-11-19 22 -

【七大类型简便计算狂刷题】四下数学+答案

2025-03-18 6

2025-03-18 6 -

【课内金句仿写每日一练】四下语文

2025-03-18 6

2025-03-18 6

作者:侯斌

分类:高等教育资料

价格:15积分

属性:82 页

大小:6.14MB

格式:PDF

时间:2025-01-09

相关内容

-

期中测试A卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

期中测B试卷(试题)-2021-2022学年数学五年级上册 沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

期中测A试卷(试题)-2021-2022学年数学五年级上册沪教版(含答案)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

【七大类型简便计算狂刷题】四下数学+答案

分类:中小学教育资料

时间:2025-03-18

标签:数学计算;校内数学

格式:PDF

价格:1 积分

-

【课内金句仿写每日一练】四下语文

分类:中小学教育资料

时间:2025-03-18

标签:无

格式:PDF

价格:1 积分