微通道中弹性颗粒惯性聚集的

VIP免费

摘 要

当随机散布细颗粒的流体以低 Re 数层流流入直管时,经过一段距离的流动后,

颗粒会被稳定的聚集在一个离管道中心固定距离的同心圆环位置上运动,这种运

动特性被称为“颗粒惯性聚集”。它表明:在层流管流中,颗粒除受到流体沿主流

方向的驱动力外,还受到垂直于主流方向的横向升力的作用,这个横向升力被称

为惯性升力,是使颗粒产生惯性聚集的主要原因。本文利用 CFD 技术,对颗粒在

微通道中运动时所受横向升力进行数值研究,旨在从力学角度揭示颗粒惯性聚集

的力学特征。

根据运动相对性原理,本文提出一个描述单颗粒在无限长通道内稳定运动的

准定常计算模型,采用 CFD 技术,研究了具有一定尺寸的球状颗粒在方形截面微

通道中所受横向升力的空间分布特征及其受影响因素,并分析了其组成成份。研

究结果表明:颗粒受到的横向升力沿通道径向呈规则的空间分布,在数值上先正

后负且存在唯一的零点,这即是颗粒的惯性聚集点;横向升力主要包含压力横向

升力和剪切横向升力的贡献,而前者是使颗粒产生惯性聚集现象的决定性因素。

本文提出一个反映颗粒表面受力与弹性变形的线性模型,据此利用 CFD 技术,

数值研究了弹性颗粒在微通道中运动的力学特征,揭示了颗粒外形改变对其横向

升力及聚集平衡位置的影响特点。研究结果表明:颗粒在壁面附近产生的弹性变

形较大;颗粒的弹性变形,会产生一个附加横向升力,且越靠近通道壁面,这个

附加横向升力将变得越大。这个附加横向升力主要由压力横向升力构成,其方向

始终指向通道中心;弹性颗粒所受横向升力的空间分布特征与刚性颗粒相似,但

弹性颗粒的聚集位置更靠近通道中心,且随着颗粒弹性的增大,其惯性聚集点偏

向通道中心。

关键词:颗粒惯性聚集 弹性变形 惯性升力 低Re 数层流 微通道流

关键词:数值研究

ABSTRACT

When a flow with randomly distributed small particles enters a pipe with low

Reynolds number, the particles are to be focused to an annulus centered at the axis of

pipe after a migration distance, which is called as inertial focus of particles. This

phenomenon indicates that in the creeping flow there are lateral forces exerted on the

immersed particles besides the driving forces. This lateral force is also called as the

inertial lift which is the main reason for the inertial focus of particles. In this paper,

CFD technique is adopted to numerically investigate the lateral lift exerted on the

moving particle inside a micro channel, aiming at revealing the mechanical

characteristics of the inertial focus of particles.

According to the principle of relative motion, a quasi-steady numerical model was

proposed to describe the stable motion of a single particle in an infinite straight channel,

by which, combined with CFD technique, the spatial features and influence mechanism

of the lateral lift exerted on the particle are numerically investigated when a spherical

particle with certain size moves in squared cross-sectional micro channel, and the

components of the lateral lift are also discussed. The results indicate that the lateral lift

show a spatially regular distribution along the radial direction. Meanwhile the

magnitude of the lift radially changes from positive to negative, with unique radial

position of zero lift, which is just the equilibrium position for the inertial focus of the

particles. The lateral lift consists of two components pressure lift and viscous shear lift,

but the former is the determinant to the inertial focus of the particles.

A numerical model for the elastic particle is established to reflect the relationship

between the stress applied on the particle’s surface and its corresponding elastic

deformation. Based on this model, CFD technique is adopted to numerically investigate

the inertial focus of elastic particles and the emphasis is on the influence of deformation

of the elastic particle on the inertia lift and the aggregation equilibrium position. The

results indicate that the particle near the wall has a larger elastic deformation. The

elastic deformation will produce an additional lateral force, and the closer the particle is

to the channel wall, the larger the additional lateral force will be in magnitude. The

additional lateral force is mainly resulted from the contribution of the pressure on the

particle’s surface. The spatial feature of elastic particle’s lateral force is similar with that

of the rigid particle, and the larger the particle’s modulus of elasticity is, the closer the

particle’s aggregation position will be to the center of the channel.

Key words: Inertial focus of particle, Elastic deformation, Inertial lift,

Laminar flow with low Reynolds Number, Micro channel flow,

Numerical investigation

目 录

摘要

ABSTRACT

第一章 绪论 .................................................................................................................... 1

1.1 研究背景及意义 ................................................................................................ 1

1.1.1 颗粒惯性聚集现象 ................................................................................. 1

1.1.2 颗粒惯性聚集现象的应用及特点 ......................................................... 1

1.2 颗粒惯性聚集现象的研究进展 ........................................................................ 2

1.2.1 刚性颗粒惯性聚集现象的研究进展 ..................................................... 2

1.2.2 弹性颗粒惯性聚集现象的研究进展 ..................................................... 5

1.2.3 颗粒惯性聚集现象实际应用的进展 ..................................................... 6

1.3 本文主要工作 .................................................................................................. 10

第二章 颗粒运动力学 ................................................................................................... 11

2.1 颗粒在宏观流场中的受力 ............................................................................... 11

2.2 受限颗粒的运动 .............................................................................................. 13

2.3 本文学术观点 .................................................................................................. 15

第三章 数值模型与计算方法 ...................................................................................... 17

3.1 颗粒的相对运动模型 ...................................................................................... 17

3.2 CFD 计算方法 ................................................................................................. 19

3.2.1 物理模型建立 ....................................................................................... 19

3.2.2 网格生成 ............................................................................................... 20

3.2.3 CFD 数学模型与离散方法 .................................................................. 21

3.2.4 边界条件 ............................................................................................... 21

3.2.5 网格独立性验证 ................................................................................... 21

3.3 Simplec 算法简介 ............................................................................................ 22

第四章 微通道中刚性运动颗粒力学特征的数值研究 .............................................. 24

4.1 数值计算工况 .................................................................................................. 24

4.2 计算结果与分析 .............................................................................................. 25

4.2.1 刚性颗粒横向升力的空间分布规律 ................................................... 25

4.2.2 刚性颗粒惯性聚集特性 ....................................................................... 27

4.2.3 刚性颗粒横向升力的构成及特点 ....................................................... 27

4.3 关于二维计算模型的讨论 .............................................................................. 29

4.3.1 二维颗粒运动简化模型 ....................................................................... 29

4.3.2 网格划分与计算条件 ........................................................................... 30

4.3.3 计算结果与分析 ................................................................................... 30

4.4 本章小结 .......................................................................................................... 32

第五章 微通道中弹性颗粒力学特征的数值研究 ...................................................... 33

5.1 弹性颗粒变形的数学模型 .............................................................................. 33

5.2 数值计算方法 .................................................................................................. 34

5.2.1 颗粒表面标记点选取 ........................................................................... 34

5.2.2 运动颗粒弹性变形的计算流程 ........................................................... 35

5.3 计算工况 .......................................................................................................... 36

5.4 计算结果及分析 .............................................................................................. 36

5.4.1 弹性颗粒形变特征 ............................................................................... 36

5.4.2 弹性颗粒横向升力的空间分布规律 ................................................... 40

5.4.3 弹性颗粒横向升力的构成及特点 ....................................................... 44

5.4.4 弹性颗粒表面压力分布特性 ............................................................... 48

5.4.5 颗粒附近流谱特性分析 ....................................................................... 50

5.5 本章小结 .......................................................................................................... 52

第六章 结论 .................................................................................................................. 53

符号表 ............................................................................................................................ 54

参考文献 ........................................................................................................................ 57

攻读硕士学位期间发表的学术论文 ............................................................................ 62

致 谢 .............................................................................................................................. 63

第一章 绪论

第1页

第一章 绪论

1.1 研究背景及意义

1.1.1 颗粒惯性聚集现象

当均匀散布细颗粒的流体以低Re数层流流入圆形截面通道时,经过足够长距

离的混合后,这些颗粒会被聚集在一个离通道中心0.6倍半径距离的同心圆环上,

随主流稳定地流动。这个运动颗粒圆环最初是由Segre和Silberberg通过实验[1]发现

的,常被称为“Segre—Silberberg圆环”[2],如图1-1所示。

图1-1 “Segre—Silberberg圆环”示意图[2]

这一现象表明:颗粒在通道中随流体运动时,除了受到沿主流方向的驱动力

外,还受到垂直于主流方向的横向升力作用。驱动力会使颗粒加速运动,直到和

周围流体的速度相同,而横向升力会引起颗粒产生垂直于主流方向的横向迁移。

这个横向升力沿通道空间分布并不均匀且存在零点,这个升力零点所在位置即是

颗粒的聚集位置[2-4]。由于这种横向升力被认为是由流场惯性力引起的,因而由其

引发的颗粒聚集现象被称为“颗粒惯性聚集”[2]。

1.1.2 颗粒惯性聚集现象的应用及特点

常见工业通道内的流动一般为高Re数湍流,而低Re数层流流动相对较少。在

湍流管内,由于湍流中的流体质点存在杂乱无章的横向掺混,这使颗粒惯性聚集

现象在湍流通道内不复存在。因此在过去相当长的一段时期内,这种流动现象未

被受到足够的重视。

近年来,随着微流体机械技术的发展与生物流体领域研究的深入,低Re数层

流又重新受到重视。微流通道、生物血管等几何尺寸和内部的流速都很小,其特

微通道中弹性颗粒惯性聚集的力学特性研究

第2页

征Re数均在100以内,故其内流动属典型低Re数层流[2,4]。此时,颗粒惯性聚集作为

一种典型的流动现象广泛存在于这些微流动之中。

近年来,与微流控技术相结合,颗粒惯性聚集原理已被应用于研制惯性微流

控芯片,用于操控颗粒或流体。这种惯性微流控芯片的主要特点是无需施加任何

外力如电磁力,就可以在微通道内实现一定尺寸颗粒的聚集流动。目前已经报道

在直线型通道[5-7]、不对称弯管通道[8-10]和螺旋形弯管通道[11-13]中分别实现了颗粒

或者细胞的惯性聚集流动。基于颗粒惯性聚集原理研制的微流控芯片的优点主要

有[14]:

1)装置结构简单,无需机械或电子部件,易于作为功能模块与现有的芯片实

验室系统(Lab on a Chip)集成结合。

2)采用高流速实现颗粒聚集流动,大大提高了处理样品的通量,甚至可以与

宏观尺寸的装置相媲美。

3)颗粒惯性聚集原理对于刚性颗粒(如聚合物颗粒)和弹性颗粒(如细胞)

都适用。

4)基于颗粒惯性聚集原理研制的微流控芯片制造成本较低,因为微流控芯片

的尺寸较小,其所消耗的材料甚微,且可实现批量化生产使其制造成本大幅下降。

应用惯性聚集原理而制成的惯性微流控芯片,作为近年来出现的一个新技术,

可用于操控颗粒或流体。由于存在上述其它技术所不具备的优点,它已被广泛用

于颗粒的输运、装配、聚集、分选及样品流的混合和反应中[15]。此外,颗粒惯性

聚集原理在细胞生物学中尤其在生物分析和医疗诊断等领域中有潜在的应用前景。

近年来,根据该原理制成的微流控芯片已被成功地应用于对生物体血管内血细胞

定向运动的控制与分离。这有助于实现对不同尺寸血细胞的筛选或实现对血浆的

分离(将血细胞从血液中分离后得到的液体即为血浆)[14-15]。

1.2 颗粒惯性聚集现象的研究进展

1.2.1 刚性颗粒惯性聚集现象的研究进展

颗粒惯性聚集现象最早于1961年,由Segre和Silberberg通过实验研究发现[1]。

他们在研究Re数为1-100、尺寸为毫米级的颗粒在直径为厘米级的圆形截面通道中

运动时发现:通道进口均匀分布的悬浮颗粒经过足够长距离的混合后,会稳定的

被聚集在离通道中心0.6倍半径距离处的环形区域上,并随流体一起运动。这就是

最初所发现的颗粒惯性聚集现象。

随后,学者们对惯性聚集现象做了大量的研究,他们试图在理论上解释这种

特殊的现象,但前期的这些理论在实际应用中都存在一定的局限[15-19]。这些研究

相关推荐

-

跨境电商商业计划书模版VIP免费

2025-01-09 27

2025-01-09 27 -

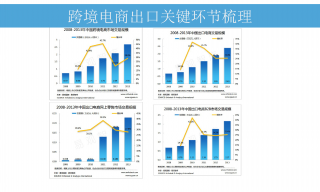

跨境电商方案范文VIP免费

2025-01-09 14

2025-01-09 14 -

创业计划书VIP免费

2025-01-09 18

2025-01-09 18 -

xx生鲜APP计划书VIP免费

2025-01-09 12

2025-01-09 12 -

跨境电商创业园商业计划书(盈利模式)VIP免费

2025-01-09 8

2025-01-09 8 -

跨境电商计划书VIP免费

2025-01-09 13

2025-01-09 13 -

绿色食品电商平台项目计划书VIP免费

2025-01-09 22

2025-01-09 22 -

农产品电子商务商业计划书VIP免费

2025-01-09 9

2025-01-09 9 -

农村电商平台商业计划书VIP免费

2025-01-09 13

2025-01-09 13 -

生鲜商城平台商业计划书VIP免费

2025-01-09 21

2025-01-09 21

作者:赵德峰

分类:高等教育资料

价格:15积分

属性:66 页

大小:3.95MB

格式:PDF

时间:2025-01-09