复叠式空气源热泵热水器除霜控制方法实验研究

VIP免费

摘 要

复叠式热泵热水机组可在环境温度为-25℃下制取 80℃的热水,当机组在室

外环境温度低于 5℃运行时,存在结霜和除霜的问题。目前,常规易结霜区域(室

外环境温度在-7℃~5℃)下的结霜和除霜规律研究较多,而对更低室外环境温度

(-18℃~-7℃)下结霜和除霜规律相应的研究较少,因此,本文以复叠式热泵热

水机组为研究对象,研究在较大的室外温度和湿度变化范围内的结霜规律和除霜

控制策略。

首先,通过对我国东北三个城市气象参数分析,发现-18℃~-7℃室外温度下,

室外相对湿度在 70%以上的天气占有一定的比例,由于相对湿度大于 70%时的结

霜风险较大,所以本文主要针对 70%~90%的相对湿度进行研究。

然后,本文将对复叠式空气源热泵热水器在焓差环境室中器机组进行结霜实

验研究,该机组低温级采用 R410A 作为循环工质,蒸发温度可达-40℃。本文所

研究的室外温度范围为-18℃~6℃、相对湿度范围为 70%-90%,共进行了 20 次实

验,获得了结霜特性(即结霜量),以及结霜对机组性能的影响,主要包括结霜

时机组 COP、换热量、耗电量、盘管温度以及高、低温级吸、排气温度和压力等

参数。

除霜试运行实验及除霜实验在结霜实验基础上进行,除霜试运行实验主要为

了获得现有的时间-温差除霜控制方法所需要的控制参数;除霜实验主要为了验证

验证优化后的除霜控制方法以及结霜实验中得到的结霜因子(结霜量与结霜时间

以及盘管温度与露点温度差的比率)。

通过实验研究,本文首先得出结霜量随结霜时间几乎呈线性变化,当结霜量

达到一定程度,将对机组性能产生很大的影响;其次,根据结霜实验总结出带亲

水层的翅片管换热器的结霜因子,其值为 8.58×10-4 kg/(m2·℃·min) ,可以通过它

对机组低温级蒸发器表面的结霜量进行预判;再者,通过除霜试运行实验获得不

同室外环境温度下机组除霜时的各个参数,根据这些参数优化了时间-温差除霜控

制方法,通过几个工况除霜实验发现机组运行良好,没有出现误除霜或除霜不尽

的现象,且机组运行性能均能保持较高状态,除霜后机组的平均 COP 相对机组正

常运行时的 COP 下降不会超过 15%;再者,在除霜实验中发现,当室外温度低

于某一值(实验发现这个临界点在-12℃~-9℃之间)时,热气旁通除霜法除霜将

无法除尽低温级蒸发器上的霜层,之后对出现这种情况的原因进行分析,并给出

采用电加热除霜所需的功率。最后,把结霜实验中总结出的结霜因子作为除霜控

制策略中的一个条件进行除霜实验,并把除霜时间的实验值和理论值进行比较,

发现其差值不是很大,考虑到计算和实验时有很多因素影响除霜时间,因此可以

证明利用结霜因子对除霜进行预判并根据其判断结果进行除霜控制有一定的可行

性。

关键词:复叠式热泵 结霜 除霜方法 除霜控制方法 结霜因子

ABSTRACT

The experimental study of frosting and defrosting features based on the cascade

type air-source heat pump water heater is not only in the easy frosting area(outdoor

temperature is from -7℃ to 6℃), but also in the lower outdoor temperature(from -18℃

to -7℃) in this paper. And the heat water can achieve the goal of the production of 80℃

hot water under -25℃ ambient environment.

First,meteorological parameters of three cities in northeast China have been

analyzed to demonstrate the significance of the study, finding the climate is common

that outdoor temperature is from -18℃ to -7℃and outdoor relative humidity is from

70% to 90%.

The frosting experiment based on the cascade type unit is carried out in the

enthalpy-difference lab.And the water heater includes the low temperature level cycle

and the high temperature level cycle. In the low temperature level cycle, R410A is

used as the refrigerant, while in the high temperature level cycle, R134a is used as the

refrigerant. In addition, the outdoor environmental conditions include that the outdoor

temperature is from -18℃ to 6℃ and outdoor relative humidity is from 70% to 90%

in this experiment. According to the frosting experiment, some parameters would be

obtained, including the coefficient of performance (COP), the amount of heat exchange

and the power of the heat pump unit, the evaporator coil temperature in the low

temperature level cycle and the intake and exhaust gas temperature and pressure in the

high or low temperature level cycle, etc.

Based on the frosting experiment, the trial operation experiment of defrosting is

carried out and the Time-Temperature difference defrosting control method is

optimized. Finally, the optimized control method and the frosting factor (the ratio of

the frosting amount and the frosting-time and the difference of the outdoor temperature

and the evaporator coil temperature in the low temperature level cycle) is also verified

by the following defrosting experiments.

Experimental results are described below. Firstly, the amount of frosting almost

changes linearly with the frosting time, and when the frosting amount reaches a certain

level, the unit performance will be made great influences. Secondly, the frosting factor

generalized in the frosting experiment which is 8.58×10-4 kg/(m2·℃·min) can predict

the frosting amount on the surface of evaporator coil and be used to the starting

condition of defrosting. At the same time, the reasonably and feasibility of the frosting

factor are proved by the comparison of the theoretical and experimental values and the

difference of the theoretical and experimental values is not large. Thirdly, the

Time-Temperature difference defrosting control method which is optimized by the trial

operation experiment of defrosting is imported into PLC of the unit. Then, the heat

pump unit with the new control method is operated and the running results demonstrate

that “the phenomenon of mistaken defrosting or incomplete defrosting” is not found

and the unit operating performance keep well,namely the difference of the average

coefficient of performance after defrosting and the normal coefficient of performance

is not more than 15%. In the end, the shortcoming of the defrosting method of hot gas

bypass is found by the defrosting experiment that when outdoor temperature below a

certain value (the value is located between -12℃ and -9℃), the frost layer on the

surface of the evaporator coil in the low temperature level cycle can be cleaned

incompletely by the defrosting method. To the later convenience of selecting the

electric heating defrosting method, the power of the electric heater is calculated in the

paper.

Key Word: cascade heat pump, frosting, defrosting methods,

defrosting control methods, frosting factor

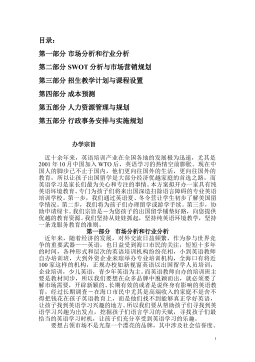

目 录

第一章 绪论 .................................................................................................................... 1

1.1 课题的来源 ............................................................................................................ 1

1.2 本课题的提出及意义 ............................................................................................ 2

1.3 本领域目前的国内外先进水平 ............................................................................ 2

1.3.1 霜层基本特性研究 ......................................................................................... 3

1.3.2 结霜工况下空气源热泵系统性能研究 ......................................................... 3

1.3.3 除霜及除霜控制方法的研究 .......................................................................... 5

1.4 本章小结 ................................................................................................................ 8

第二章 复叠式空气源热泵热水器的介绍及应用 ........................................................ 9

2.1 复叠式热泵系统的理论循环 ................................................................................ 9

2.2 复叠式空气源热泵系统结构及部件 ..................................................................... 9

2.2.1 复叠式空气源热泵系统结构 .......................................................................... 9

2.2.2 复叠式空气源热泵系统部件 ........................................................................ 10

2.3 复叠式空气源热泵热水器的控制系统 .............................................................. 11

2.4 复叠式热泵热水器的除霜方法 .......................................................................... 14

2.5 复叠式空气源热泵的应用环境 .......................................................................... 15

2.6 本章小结 .............................................................................................................. 18

第三章 实验系统及实验方案 ...................................................................................... 19

3.1 实验系统 ............................................................................................................... 19

3.1.1 焓差环境实验室 ........................................................................................... 19

3.1.2 复叠式空气源热泵热水器 ........................................................................... 20

3.1.3 实验的测量系统 ........................................................................................... 20

3.2 实验方案 .............................................................................................................. 25

3.2.1 实验目的 ........................................................................................................ 25

3.2.2 实验方法 ....................................................................................................... 25

3.2.3 实验工况确定 ............................................................................................... 27

3.2.4 实验测点的确定 ........................................................................................... 27

3.3 本章小结 .............................................................................................................. 29

第四章 复叠式热泵热水器的结霜特性 ...................................................................... 30

4.1 结霜特性 .............................................................................................................. 30

4.1.1 结霜量的计算 ............................................................................................... 30

4.1.2 结霜量随时间的变化关系 ........................................................................... 31

4.2 结霜对机组性能参数的影响 .............................................................................. 35

4.2.1 不同室外环境温度下结霜对机组 COP 和换热量的影响 .......................... 35

4.2.2 不同相对湿度下结霜对机组换热量和 COP 的影响 .................................. 37

4.2.3 结霜对机组高、低温级吸、排气温度的影响 ............................................ 40

4.2.4 结霜对高、低温级吸、排气压力的影响 ................................................... 43

4.3 除霜控制方法判定条件探讨 .............................................................................. 46

4.3.1 室外温度与盘管温差及室外露点温度与盘管温度差随结霜量的变化 ... 46

4.3.2 室外露点温度与盘管温度差作为除霜判断条件理论分析 ....................... 48

4.3.3 结霜因子的提出 ........................................................................................... 49

4.4 本章小结 .............................................................................................................. 50

第五章 复叠式空气源热泵的除霜控制方法实验研究 .............................................. 51

5.1 机组除霜试运行实验 .......................................................................................... 51

5.1.1 机组除霜试运行时的除霜逻辑 .................................................................... 51

5.1.2 试运行时的实验数据处理 ............................................................................ 56

5.2 除霜控制策略的优化 .......................................................................................... 60

5.3 除霜控制策略优化后的机组的运行情况 .......................................................... 65

5.3.1 优化后机组运行性能分析 ........................................................................... 65

5.3.2 优化后机组运行误除霜或除霜不尽的情况分析 ........................................ 70

5.3.3 低温下除霜方法 ........................................................................................... 72

5.4 盘管温度与露点温度除霜控制法理论与实验分析 .......................................... 75

5.4.1 理论分析 ....................................................................................................... 75

5.4.2 实验结果及分析 ........................................................................................... 77

5.4.3 理论计算与实验结果对比 ........................................................................... 78

5.5 本章小结 .............................................................................................................. 79

第六章 结论及展望 ...................................................................................................... 81

6.1 结论 ...................................................................................................................... 81

6.2 今后的工作方向 .................................................................................................. 82

参考文献 ........................................................................................................................ 83

在读期间公开发表的论文和承担科研项目及取得成果 ............................................ 87

致谢 ................................................................................................................................ 88

第一章 绪论

1

第一章 绪论

1.1 课题的来源

我国正处于经济高速发展的重要时期,能源对于我国进入全面小康社会的重

要性不言而喻。早在 2006 年,中国已成为世界第二大能源生产和消费国,仅次于

美国。同时,我国的能源消费总量远大于能源生产总量。基于能源资源和产业这

一基本国情,清洁、安全、高效能源及用能装置的开发和利用越来越受到国家和

政府重视。

在众多的能源消耗行业中,建筑耗能占有很重的比例,占全国总能耗的 30%,

而其中的暖通空调能耗占建筑总能耗的 50%~60%[1],而且随着经济的发展和人

民生活水平的提高,人们对建筑的舒适性要求也在随之提高,这也将促使了暖通

空调耗能进一步提高。

热泵技术作为较为有效技术之一,它可以把不能直接利用的低位热源(如空气、

土壤、水中所含的热能,太阳能,工业废热等)转换为可以利用的高位热能,从而达到

节约部分高位能(如煤、燃气、油、电等) 的目的。因此热泵是一种利用高位能使

热量从低位热源流向高位热源的节能装置,所供给用户的热量却是消耗的高位热

能与吸取的低位热能的总和。热泵已在工程实践中证明了它的可行性,它可使用

能效率和效益得到最优化组合,是科学配置能源的典范。

热泵的理论基础起源于 19 世纪早期卡诺的著作[2]。在此后相当长一段时间内,

热泵技术没有得到很好的发展,这主要是因为热泵的开发工作主要取决于能源费

用和能源利用效率,当时供热取暖方式多样化,简单价廉,因此技术经济等方面

对热泵的需求迫切性不大。热泵技术在 20 世纪中叶以后得到了快速发展,特别是

1973 年能源危机的推动。在 20 世纪末,随着京都协议的制定,减少温室效应、

保护环境成为人们关注的焦点,而热泵以其特有的节能和环保优势,又重新确立

了它的发展地位。

虽然空气源热泵有诸多优点,但是随室外环境温度降低的下降,其制热性能

也会受到很大的影响,使得冬季供热的可靠性难于保证,这成为空气源热泵系统

在寒冷地区应用的主要制约因素。由于寒冷地区冬季很长时间内环境温度都很低,

在使用空气源热泵冷热水机组供暖时会出现压缩比过高的问题,因此,在借鉴复

叠式制冷技术基础上,提出开发研制复叠式热泵循环系统[3],在更低的室外环境

温度下,使得空气源热泵系统出力高温化,使空气源热泵系统适应更恶劣的室外

环境,扩大空气源热泵系统更广阔的应用空间。

复叠式空气源热泵热水器除霜控制方法实验研究

2

复叠式热泵循环系统很大的提高了空气源热泵的效率,但它与普通的空气源

热泵一样,还要面临结霜和除霜的问题。在冬季,空气源热泵在进行制热循环时,

当空气露点温度高于蒸发器翅片表面温度,换热器翅片表面就会结露;当翅片温

度低于0℃时,翅片表面就会结霜。霜是由冰晶构成的多孔性松散物质,其热阻随

霜层厚度变化而变化,随着霜的形成与增长,蒸发器表面与空气间的传热热阻也

随之增加,而且还会加大空气流动的阻力,使通过蒸发器的空气流量下降,导致

由空气向蒸发器的传热量下降,热泵机组的工作状况不断恶化,以致不能正常工

作。因此,为了保证空气源热泵可靠、高效工作,必须对其进行周期性的除霜。

复叠式空气源热泵与普通空气源热泵的结霜与除霜有很大的不同。首先,复

叠式空气源热泵分为高温级循环和低温级循环,结霜的位置是在低温级蒸发器上;

其次,由于复叠式空气源热泵的工作温度范围相对较广(以本论文研究的空气源热

水器机组为例,可冬季可在-25℃的室外温度下制得80℃热水),因此,在考虑普

通空气源热泵易结霜的室外温度区间(即5~-7℃)同时,还应考虑更低室外温度下

低温级蒸发器的结霜和除霜问题。

1.2 本课题的提出及意义

如前所述,目前国内对于空气源热泵结霜除霜的研究主要集中在易结霜的温

度区间(即5~-7℃),而对于更低温度的结霜除霜问题的研究很少涉及,一般认为

更低温度下空气中的含湿量很少,以至于空气源热泵很难结霜或者结霜很少,而

且普通空气源热泵的运行温度很少在更低温度下运行,所以本文以复叠式空气源

热泵热水器机组为研究对象,方便研究更低温度下空气源热泵的结霜及除霜特性。

对于实际环境中,当温度达到-10℃甚至更低时,空气中的相对湿度是有可能

达到75%以上的,我国北方有很多城市都有这种低温高湿的天气,例如哈尔滨、

长春等,这些城市的气象参数在第二章作详细叙述。

1.3 本领域目前的国内外先进水平

对于空气源热泵结霜和除霜问题,国内外研究者们从各个方面、用不同方法

进行研究工作,研究所用方法大致可分为实验测量和数值计算、模拟这两种,本

节主要总结实验测量的方法,根据已有的研究,可以把其大致归纳为霜层基本特

性研究、结霜时空气源热泵系统性能研究与除霜方法及除霜控制方法的研究。

第一章 绪论

3

1.3.1 霜层基本特性研究

对霜层基本特性的实验研究即为对霜层特性实验测量,实验测量主要为了获

得霜层厚度、结霜量、霜密度及导热系数,但用实验的方法测量并精确的得到这

些参数一般比较困难,现有的一些方法有的可以较为准确的测量,也被很多研究

者们所引用。

首先,对于霜层厚度和密度的测量。Hosoda T.等[4]采用照相方法研究平板上

霜层厚度的变化。后来于兵等[5]用CCD摄相、以图像处理方法为辅代替Hosoda T.

的方法,将早期主要针对简单几何形状表面结霜研究推广到翅片管换热器霜层厚

度测量,并进一步发展到采用显微成像、以图像处理为辅的技术,目前他的方法

被众多的研究者所采用。除此之外,Bwseant R W[6]使用了激光测霜厚、移片测霜

密度的方法。移片测霜密度就是在冷壁面上帖附薄的圆片,待结霜后将附有霜的

薄圆片取下,并称其重量,然后再用数字千分尺测量霜层的厚度,计算出霜的体

积,最后算出霜的密度。

除了霜层厚度和密度的测量之外,结霜量的测量也是相当重要的,研究人员

为了得到结霜量,想出了各种测量方法。其中一种方法是称重法,包括以下几种:

Senshu T等[7]为了获得结霜的质量,先测出没结霜时换热器翅片管的质量,再在

实验中每隔一段时间将结满霜的换热器翅片管卸下,称量结满霜的换热器翅片管

的质量,然后减掉初始换热器的质量就得出结霜量;Xia Y等[8]是用称量化霜水的

方法得到结霜量,具体是用电子天平测量一个除霜周期(即从机组开始结霜到除

霜结束)的化霜水质量,化霜水的质量就为蒸发器的结霜量。Shinhyuk Yoon等[9]

用可移动取样带取霜样品称质量,在每次测量之前,先称出要放到换热器的表面

铝带的质量,之后把铝带放在换热器的表面,然后在一定结霜时间之后,取下布

满霜的铝带,并用天平测量。以上几种方法测量起来繁琐并不易实现,为此

0’Neal[10]根据测量流通蒸发器的空气流量和进出口的湿度差,间接算出沉积为霜

的水汽重量。这些方法一般测量结果都会产生一些的不确定,但相对而言,0’Neal

的这种测量换热器前后含湿量和通过换热器的风量的方法由于容易实现、误差较

小,国内外研究者们使用此种方法的较多[11][12][13],其可行性也得到了很好的验证。

1.3.2 结霜工况下空气源热泵系统性能研究

空气源热泵的蒸发器表面结霜不是孤立的,它不但会对空气源热泵换热器的

自身换热性能产生影响,还会对热泵系统的冷凝压力、蒸发压力、过冷度及换热

量等参数产生影响,从而影响系统整体运行性能;系统参数由于结霜引起的变化

复叠式空气源热泵热水器除霜控制方法实验研究

4

反过来又会对换热器表面的霜层生长特性产生影响。因此,换热器的结霜过程与

热泵系统运行过程是不可分割的整体,二者综合起来考虑,才能真实反映结霜工

况下空气源热泵系统实际工作过程。

对于研究结霜工况下空气源热泵机组整体的性能,国外研究研究者们研究的

较早。Millerw.A.等[14] ,他们对一台额定制热量为7.5KW的分体空气源热泵在三

组不同的环境温湿度条件下的运行情况进行了研究,测量了制热工况下的结霜及

除霜过程中的制热量、空气侧压降、COP等系统参数,实验结果表明结霜对空气

源热泵系统性能的影响不大。Kamil Kaygusuz[15]在环境温度在-10~4℃ 、相对湿

度在65%-80%的范围内,对一台为75m2房间供暖的空气源热泵的工作性能进行了

研究,在系统达到稳定的结霜工况时,测出系统性能参数和换热量。Watters R.J.

等[16] 对空气源热泵的蒸发器翅片片距对结霜除霜影响进行了研究,利用实验研

究了双排管蒸发器家用热泵系统的结霜、除霜性能,测量出了霜层厚度、结霜量、

热泵系统制热量、COP等参数,表明改善蒸发器盘管的布置,可以对结霜除霜产

生很大影响。

国内一些学者近年来也对空气源热泵的蒸发器结霜对机组性能的影响进行了

研究。黄虎等[17]对一台70.34KW空气源热泵冷热水机组在结霜工况下的运行情况

进行了测试,得出在这个结霜工况下运行时,机组吸、排气压力、翅片温度、制

热量、压缩机功率、风机电流、霜层厚度等参数随时间的变化关系。姬长发等[18] 在

一台制冷量为55kW的空气源热泵冷热水机组上进行了实验,他在分析中把结霜过

程分为启动阶段、稳定阶段和震荡阶段三个阶段,得出在结霜中期风速分布不均

匀会造成一些支路出口带有液体,导致热力膨胀阀的控制发生了间歇荡;在结霜后

期的,风速的不均匀分布与霜层导致传热性能的恶化结合在一块,使热力膨胀阀

发生了持续的振荡。郭宪民等[19]对一台空气源热泵空调器在不同环境条件下室外

换热器的动态结霜性能进行了实验研究,分析了进风温、湿度对热泵空调器结霜

量及霜层厚度的影响,实验中考虑了结霜对热泵系统蒸发温度及风机流量的影响,

实验结果表明室外换热器结霜量随时间线性增长,对于不同的室外工况,蒸发器

均在进风温度0~3℃附近时结霜最为严重,相对湿度对霜层厚度的影响要大于对结

霜量的影响。田津津等[20]对一台风冷热泵室进行了结霜工况下的实验测试,实验

研究了风冷热泵在规定的环境温度下制热能力、出风温度以及热泵制热性能的变

化。实验结果表明热泵结霜严重的影响了制热能力、出风温度以及热泵制热性能。

此后,王亚静等[21]对一台采用R410A工质的热泵空调器的动态结霜性能进行了实验

研究,测量了在不同结霜工况下R410A热泵空调器室外换热器表面结霜量和霜层厚

度以及热泵系统的动态性能参数。实验结果表明,在结霜后期,霜层厚度的增长

相关推荐

-

XX中学英语学科质量提升计划书VIP免费

2025-01-09 9

2025-01-09 9 -

VIPKID-美国小学在家上-在线英语学习项目商业计划书VIP免费

2025-01-09 8

2025-01-09 8 -

English TV--英语学习智能视频平台创业商业计划书VIP免费

2025-01-09 17

2025-01-09 17 -

English TV,4--英语学习智能视频平台商业计划书VIP免费

2025-01-09 16

2025-01-09 16 -

260Educotton-让孩子快乐学习英语的平板电脑商业计划书VIP免费

2025-01-09 14

2025-01-09 14 -

XX英语学校创业策划书VIP免费

2025-01-09 14

2025-01-09 14 -

Ustudy-K12英语在线学习产品商业计划书VIP免费

2025-01-09 18

2025-01-09 18 -

Strawberry English School (SES)英语培训学校计划书VIP免费

2025-01-09 24

2025-01-09 24 -

《天中英语智能电子公司创业商业计划书》VIP免费

2025-01-09 14

2025-01-09 14 -

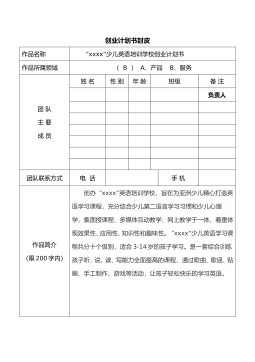

XXXX少儿英语培训学校创业计划书VIP免费

2025-01-09 23

2025-01-09 23

作者:牛悦

分类:高等教育资料

价格:15积分

属性:92 页

大小:6.23MB

格式:PDF

时间:2025-01-09

相关内容

-

XX英语学校创业策划书

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:WPS

价格:10 积分

-

Ustudy-K12英语在线学习产品商业计划书

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:PPTX

价格:10 积分

-

Strawberry English School (SES)英语培训学校计划书

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:DOC

价格:10 积分

-

《天中英语智能电子公司创业商业计划书》

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:DOC

价格:10 积分

-

XXXX少儿英语培训学校创业计划书

分类:中小学教育资料

时间:2025-01-09

标签:无

格式:DOC

价格:10 积分