磁载核壳型TiO2复合光催化剂制备及其在处理染料废水中的应用研究

摘 要

本论文致力于高效 TiO2复合光催化材料的设计制备、表征及其光催化性能研

究,针对所合成复合光催化材料的特点,系统研究了不同组分掺杂、不同合成方

法对复合材料晶型结构与表面物理化学性质的影响,通过染料废水中有机污染物

的降解来考察该系列复合 TiO2纳米材料的光催化性能。

本文采用程序升温水热法与超声均相沉淀法相结合技术,制备了磁载核壳型

TiO2复合光催化剂如γ-Fe2O3/SiO2/TiO2纳米粒子、Fe3O4/TiO2等。通过 X射线粉

末衍射光谱(XRD)、扫描电子显微镜(SEM-EDS)、X-射线光电子能谱(XPS)测

试、透射电子显微镜(TEM 与HRTEM)、N2吸附、紫外可见固体漫反射(UV-Vis

DRS)测定等表征手段对合成材料的组成、结构、晶相及表面物理化学特性进行

了表征以及光催化性能人研究。

γ-Fe2O3/SiO2/TiO2复合光催化材料测试结果表明,γ-Fe2O3/SiO2/TiO2纳米核壳

结构复合光催化材料中的 TiO2以锐钛矿相存在,并且 γ-Fe2O3/SiO2/TiO2粒子的粒

径在 100nm左右,γ-Fe2O3/SiO2均匀地分散在 TiO2中,γ-Fe2O3/SiO2粒径大概 20nm

以及 SiO2层大概是 2nm~6nm,γ-Fe2O3/SiO2/TiO2光催化剂发生红移现象,在紫外

光范围内具有强烈的光吸收性能,且在可见光区 400nm~600nm 也有部分吸收,

从而使 TiO2的吸光范围变宽。γ-Fe2O3/SiO2/TiO2纳米核壳结构复合光催化剂在空

气中 450 ℃煅烧后,纳米 γ-Fe2O3/SiO2/TiO2磁性迅速降低,磁载核壳型

γ-Fe2O3/SiO2/TiO2复合光催化材料为双孔微孔-介孔结构,比表面积大。

另外,光催化反应中,研究 Fe:Ti 比、溶液初始 pH、催化剂投加量、溶液初

始浓度等不同因素对光催化降解效果的影响,γ-Fe2O3/SiO2/TiO2纳米核壳结构复

合光催化剂对罗丹明 B(RhB)染料光催化降解最好,在90min 内罗丹明 B(RhB)染

料转化率为 95%,其次是甲基橙(MO)90min 基本上转化率为 90%,与纯的 TiO2

相比,γ-Fe2O3/SiO2/TiO2复合光催化剂有较高的光催化活性,其降解效果的最佳

条件为:γ-Fe2O3/10%SiO2/45%TiO2复合光催化剂在酸性(pH=2)环境下降解效

果最佳,Fe 与Ti 比值为1:1 时,催化剂投加量的最佳值为 2.0g/L,催化剂循环使

用5次未发现活性有明显光催化活性下降。因此,γ-Fe2O3/SiO2/TiO2催化剂分离

回收简单,具有可观的应用前景。

Fe3O4/TiO2复合光催化材料测试结果表明,Fe3O4/TiO2纳米核壳结构复合光催

化材料中的 TiO2以锐钛矿相存在,并且 Fe3O4/TiO2粒子的粒径在 50nm~100nm 范

围内,Fe3O4均匀 地 分散 在 TiO2中 , Fe3O4粒径 大概 20nm,Fe3O4/TiO2在

200nm~600nm 都有吸收,从而使 TiO2的吸光范围变宽,表明有 FeTiO3生成,。

Fe3O4/TiO2纳米核壳结构复合光催化剂在 N2保护中450℃煅烧后,纳米 Fe3O4/TiO2

磁性迅速降低,磁载核壳型 Fe3O4/TiO2复合光催化材料为双孔微孔-介孔结构,比

表面积大,有利于染料吸附在 Fe3O4/TiO2复合光催化材料表面,较快光催化反应。

另外,光催化反应中,在 120min 内罗丹明 B(RhB)染料转化率为 95%,研究

Fe:Ti 比对光催化降解效果的影响,36.7%Fe3O4/TiO2,即 Fe 与Ti 比值为1: 2 时,

Fe3O4/TiO2核壳结构复合光催化剂对染料废水罗丹明 B(RhB)(10mg/L 50mL)

降解,动力学方程的反应速率常数是 0.0332 min-1,反应速率常数最大。

通过分析 Fe3O4/TiO2光催化反应机理研究降解机理得出:( ⅰ)在光催化过程

中,Fe3O4/TiO2复合光催化剂中首先是 TiO2吸收紫外光,产生光生电子/空穴对

(

he /

),(ⅱ)FeTiO3和TiO2之间存在的协同效应,FeTiO3能够迅速捕获 TiO2

表面的导带(CB)电子(

e

), 其结果也就是加快了导带电子的迁移速度,减少

了TiO2表面光生

he /

对之间的快速复合几率,FeTiO3的禁带能是 2.85eV,使得

Fe3O4/TiO2复合材料的光吸收带变宽,带隙能降低,电子更容易发生跃迁,产生

更多的光生电子和空穴,这对提高了复合材料的光催化活性也起到积极的作用。

关键词:二氧化钛 磁载 核壳型 γ-Fe2O3 Fe3O4 光催化 水热合成法

染料废水

ABSTRACT

A series high performance TiO2 photocatalytic composits were prepared and

well-characterized, and their catalytic activities were studied. Based on the

characteristic of prepared nanocomposits, it was systemically discussed that the

crystalline morphology and surface physicochemical properties of the composites were

affected by different coated constitnents and synthesized methods. Moreover, the

photocatalytic activities of as-prepared composites were studies by the degradation of

organic pollutants including methylene blue(MB), rhodamine B(RhB), methyl

orange(MO) and congo red(CR) in the dye wastewater.

New photocatalyst and magnetic, core-shell TiO2 with anatase crystalline phase

such as γ-Fe2O3/SiO2/TiO2、Fe3O4/TiO2 was prepared by hydrothermal treatment

followed by homogeneous precipitation method with ultrasonication. Surface

morphology, crystallize phase and physicochemical properties of the γ-Fe2O3/SiO2/TiO2

core-shell composite were characterized by X-ray diffraction (XRD) patterns, X-ray

photoelectron spectroscopy(XPS), Scanning electron microscope (SEM)and energy

dispersive spectroscopy(EDS) ,Transmission electron microscopy(TEM) and

high-resolution transmission electron microscopy(HRTEM), nitrogen

adsorption/desorption determination and Vibrating Sample Magnetometer (VSM),

Ultraviolet Visible Diffuse Reflectance Spectroscopy (UV-Vis DRS), respectively.

The results show the core-shell γ-Fe2O3/SiO2/TiO2 NP with anatase TiO2 are

composites of spherical nanoparticles about 100nm in diameter, within several

γ-Fe2O3/SiO2 particles about 20nm in diameter and the SiO2 coated on the γ-Fe2O3 with

2nm~6nm, the core-shell γ-Fe2O3/SiO2/TiO2 NP generates red shift,and has higher

absorption in visible light up to a wavelength of 400nm~600nm and greater

photocatalytic activity, and the core-shell γ-Fe2O3/SiO2/TiO2 NP has additional

superparamagetism and can separate and recycle by magnetic, although its magnetism

lower than the the pure γ-Fe2O3 due to the heat treatment at 450℃. And the core-shell

γ-Fe2O3/SiO2/TiO2 NP could be attributed the stronger optical absorption ability, the

higher surface, dual-pore structures.

Furthermore, the efficiency of γ-Fe2O3/SiO2/TiO2 in photocatalytic degradation

was studied by investigating the effects of the Fe/Ti ratios, pH of the reaction solution,

catalyst amount and probably pathways were proposed. About 95% RhB decomposed in

90 min under illumination of UV light. Comparing with the pure TiO2, the high

photoactivity of as-prepared core-shell γ-Fe2O3/SiO2/TiO2 NP could be attributed the

stronger optical absorption ability. γ-Fe2O3/10%SiO2/45%TiO2 has the highest

photoactivity in the condition of pH=2, 2.0g/L γ-Fe2O3/SiO2/TiO2, Fe/Ti =1:1.In

addition, After 5 cycles, the γ-Fe2O3/SiO2/TiO2 NP also maintaines high photocatalytic

activityand catalyst recovery. The core-shell γ-Fe2O3/SiO2/TiO2 composite catalyst also

had the advantages of easily being separated and taken on a wide application prospect.

In this paper, the results show the diameter of the core-shell Fe3O4/TiO2 NP with

anatase TiO2 is about 50nm~100nm, and Fe3O4 core NP is about 20nm~30nm. The

UV-Vis DRS results showed that the core-shell Fe3O4-TiO2 coating consist of FeTiO3,

because the core-shell Fe3O4/TiO2NP has higher absorption in visible light up to a

wavelength of 200nm~700nm and it indicates the synthesis of FeTiO3 NP, which has

good light absorbance and favorable photo-excited electron–hole separation characters.

Furthermore, the band gap of bulk FeTiO3, which is 2.85 eV, is lower than that of TiO2.

In addition, the core-shell Fe3O4/TiO2 NP has additional superparamagetism, And the

core-shell Fe3O4/TiO2 could be attributed the stronger optical absorption ability, the

higher surface, dual-pore structures.

Furthermore, the efficiency of Fe3O4/TiO2 in photocatalytic degradation was

studied by investigating the effects of the Fe/Ti ratios and probably pathways were

proposed. About 95% RhB decomposed in 120 min under illumination of UV light. the

Fe3O4/TiO2 photocatatalytic reaction can be described simply by lnC0/C=kKt=Kappt, and

36.7%Fe3O4/TiO2 (Fe/Ti =1: 2)exhibites the best photocatalytic axtivity and Kapp=0.0332

min-1.

Therefore when core-shell Fe3O4/TiO2 NP is irradiated, the electron possibly

transfers to conduction band in two steps: first step:the electron is initiated from the

valence band to the conduction band of TiO2 and second step: the electron in the

conductionband of TiO2 injects to the conduction band of FeTiO3. For this two-step

mechanism, the lifetime of excited hole and electron pair was prolonged. Perhaps the

improved efficiency of the photon is another reason for the good photocatalytic activity

of the 36.7%Fe3O4/TiO2 coatings.

Key words: TiO2,Magnetic,Core-Shell Structure,γ-Fe2O3, Fe3O4,

Photocatalytic,Programmed Temperature Hydrothermal Treatment,

Dye wastewater

目 录

中文摘要

ABSTRACT

第一章 绪 论 ...................................................................................................................1

1.1 光催化化学 ........................................................................................................... 1

1.2 半导体光催化化学 ............................................................................................... 2

1.2.1 半导体的能带结构 ......................................................................................... 2

1.2.2 半导体光催化基本原理 ................................................................................. 3

1.2.3 半导体金属氧化物光催化研究现状 ............................................................. 5

1.3 磁载核壳型 TiO2复合光催化剂 .......................................................................... 6

1.3.1 磁载核壳型 TiO2复合光催化剂的基本概念 ................................................ 7

1.3.2 核壳型复合光催化剂形成过程及其作用机理 ............................................. 7

1.3.3 磁载核壳型 TiO2复合光催化剂制备方法 .................................................... 8

1.3.3.1 溶胶-凝胶法............................................................................................... 8

1.3.3.2 均相沉淀法 ................................................................................................ 9

1.3.3.3 微乳液法 .................................................................................................... 9

1.3.3.4 原位生长法 .............................................................................................. 10

1.3.3.5 微波水热法 .............................................................................................. 10

1.3.4 核壳型复合光催化剂研究现状 ................................................................... 10

1.4 磁核材料 ............................................................................................................. 12

1.4.1 纳米 Fe3O4的制备与性质 ............................................................................ 13

1.4.2 纳米 γ-Fe2O3的性质 ..................................................................................... 14

1.5 磁载 TiO2复合光催化剂在水处理方面的应用 ................................................ 14

1.6 论文选题目的及意义 ......................................................................................... 16

第二章 磁载核壳型 TiO2复合光催化剂的制备与表征 ..............................................18

2.1 磁载核壳型 TiO2复合光催化剂的制备 ............................................................ 18

2.1.1 实验试剂与仪器 ........................................................................................... 18

2.1.2 磁载核壳型 TiO2复合光催化材料的制备过程 .......................................... 19

2.1.1.1 磁基质(Fe3O4)的制备.............................................................................. 19

2.1.1.2 Fe3O4/SiO2纳米粒子的制备 .................................................................... 20

2.1.1.3 γ-Fe2O3/SiO2/TiO2纳米粒子的制备 ........................................................ 21

2.1.1.4 Fe3O4/TiO2纳米粒子的制备 .................................................................... 22

2.2 磁载核壳型 TiO2复合光催化剂的表征 ............................................................ 23

2.2.1 X 射线粉末衍射光谱(XRD)分析 ............................................................ 23

2.2.2 X 射线光电子能谱(XPS)测试 ...................................................................... 23

2.2.3 扫描电子显微镜(SEM-EDS)分析 .......................................................... 24

2.2.4 透射电子显微镜(TEM)和(HRTEM)分析 .............................................. 24

2.2.5 N2吸附-脱附(N2-adsorption-desorption) ................................................. 24

2.2.6 VSM 分析 ....................................................................................................... 25

2.2.7 紫外可见固体漫反射(UV-Vis DRS)分析 .............................................. 25

第三章 磁载核壳型 γ-Fe2O3/SiO2/TiO2光催化剂结构与光催化性能的研究............27

3.1 γ-Fe2O3/SiO2/TiO2复合光催化剂的结构与讨论................................................ 27

3.1.1 X 射线粉末衍射光谱(XRD)分析 ............................................................ 27

3.1.2 X 射线光电子能谱(XPS)测试 ...................................................................... 28

3.1.3 扫描电子显微镜(SEM) ........................................................................... 30

3.1.4 透射电子显微镜(TEM)和(HREM)分析................................................. 31

3.1.5 N2吸附-脱附(N2-adsorption-desorption) ................................................. 32

3.1.6 VSM 分析 ....................................................................................................... 34

3.1.7 紫外可见固体漫反射(UV-Vis DRS)分析 .............................................. 35

3.1.8 小结 ............................................................................................................... 36

3.2 光催化性能研究 ................................................................................................. 37

3.2.1 实验仪器和试剂 ........................................................................................... 37

3.3.2 光催化反应 ................................................................................................... 38

3.2.3 结果与讨论 ................................................................................................... 39

3.2.3.1 γ-Fe2O3/SiO2/TiO2对不同化学结构染料的光催化活性 ........................ 39

3.2.3.2 γ-Fe2O3/SiO2/TiO2与TiO2的光催化性能的比较 ................................... 43

3.2.3.3 Fe/Ti 比值对 γ-Fe2O3/SiO2/TiO2光催化活性的影响.............................. 43

3.2.3.4 溶液初始 pH 对γ-Fe2O3/SiO2/TiO2光催化活性的影响 ....................... 44

3.2.2.5 γ-Fe2O3/SiO2/TiO2催化剂投加量对光催化活性的影响 ........................ 46

3.2.3.6 γ-Fe2O3/SiO2/TiO2复合光催化剂的再生与循环 .................................... 47

3.3 γ-Fe2O3/SiO2/TiO2光催化反应机理研究............................................................ 48

3.4 小结 ..................................................................................................................... 49

第四章 磁载核壳结构 Fe3O4/TiO2复合光催化材料的结构与光催化性能的研究 ...51

4.1 Fe3O4/TiO2表征结果讨论 ................................................................................... 51

4.1.1 X 射线粉末衍射光谱(XRD)分析 ............................................................ 51

4.1.2 扫描电子显微镜(SEM) ........................................................................... 52

4.1.3 透射电子显微镜(TEM)和(HREM)分析................................................. 52

4.1.4 N2吸附-脱附(N2-adsorption-desorption) ................................................. 54

4.1.5 VSM 分析 ....................................................................................................... 55

4.1.6 紫外可见固体漫反射(UV-Vis DRS)分析 .............................................. 56

4.2 磁载核壳型 Fe3O4/TiO2光催化性能的研究 ..................................................... 57

4.2.1 光催化实验内容 ........................................................................................... 57

4.2.2 实验结果与讨论 ........................................................................................... 57

4.2.2.1 Fe3O4 /TiO2光催化剂与 TiO2的光催化性能的比较.............................. 57

4.2.2.2 Fe 与Ti 比值对 Fe3O4/TiO2光催化剂光催化活性的影响 .................... 59

4.2.2.3 Fe3O4/TiO2光催化剂的再生与循环 ........................................................ 61

4.3 Fe3O4/TiO2纳米结构的形成机理 ....................................................................... 62

4.4 小结 ..................................................................................................................... 63

第五章 结 论 .................................................................................................................65

5.1 磁载核壳型 γ-Fe2O3/SiO2/TiO2光催化剂结构与光催化性能的研究.............. 65

5.2 磁载核壳型 Fe3O4/TiO2光催化材料的结构与光催化性能的研究 ................. 66

参考文献 .........................................................................................................................68

在读期间公开发表的论文和承担科研项目及取得成果 .............................................73

致 谢 ...............................................................................................................................74

第一章 绪论

1

第一章 绪 论

1.1 光催化化学

所谓光化学反应,是指一个原子、分子、自由基或离子吸收一个光子所引发

的化学反应。光催化化学作为光化学的一个分支,开始于20世纪70年代,1972年

Fujishima A和Honda K在Nature杂志上发表了关于n型半导体TiO2单晶电极上光致

分解水并产生氢气和氧气的论文[1],这一重要发现标志着多相光催化时代的开始,

同时也揭开了TiO2作为光催化材料发展的序幕,更为人类开发利用太阳能开辟了新

的途径。最初的光催化反应是指光照引发的一系列催化反应,而当时的光催化剂

实质上为光化学敏化剂,如半导体型金属硫化物(CdS)和氧化物(TiO2、CdO、

ZnO、ZrO2和WO3)。

当今,解决环境污染问题是人类面临的最严峻的挑战之一。由于全球工业化

进程的加快发展,环境污染已从局部波及到全球,尤其是印染废水对环境的污染,

严重破坏了生态平衡,甚至威胁到人类的生命。染料废水是世界范围内几种难治

理的行业性废水之一,具有COD高,而BOD/COD值低,种类多、水质成分复杂、

色度深、毒性大和可生物性差等特点。从化学结构来分析,染料化学结构的种类

繁多,但其共同特征都具有一定的共轭双键和杂环,常见的结构有偶氮型、蒽醌

型、酞箐型、三芳基甲烷型、噻嗪型、恶嗪型、丫嗪型和各种稠环杂环等,因而

探索快速而有效地脱色和降解染料废水是国内外水处理研究的热点。近年来,多

相光催化技术在环境污染控制领域得到了广泛的应用,它是一种能够深度降解和

矿化环境污染物的高级氧化技术,且不会产生二次污染,光催化剂有望直接利用

太阳光中的可见光作为激发光源来驱动氧化-还原反应,而且对有机污染物不具有

选择性,应用范围广。从能源利用角度来讲,这一特征使光催化技术更具有开发

前景。而传统的处理方法如物理吸附法、化学氧化法只能将有害的物质从一相转

到另一相,或是将污染物分离/浓缩,不能彻底消除有害源;微生物生物处理法和

高温焚烧法虽然能有效降解有机污染物,但易产生二次污染;传统方法还有投资

大、能耗高、处理不彻底等缺点。因此,光催化氧化技术作为一种高级氧化技术[2-7],

有望为降解和矿化染料废水中的有机污染物开辟一条行之有效的途径。

相关推荐

-

生态农业项目商业计划书VIP免费

2024-12-31 30

2024-12-31 30 -

牛奶创业计划书VIP免费

2024-12-31 6

2024-12-31 6 -

南京现实版开心农场VIP免费

2024-12-31 8

2024-12-31 8 -

绿色蔬菜农产品批发创业计划书VIP免费

2024-12-31 10

2024-12-31 10 -

绿色农产品销售创业计划书VIP免费

2024-12-31 8

2024-12-31 8 -

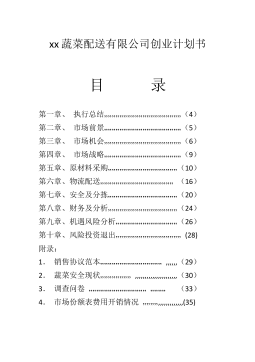

xx蔬菜配送有限公司创业计划书样本VIP免费

2025-01-09 5

2025-01-09 5 -

现代农业生态园创业计划书范文VIP免费

2025-01-09 12

2025-01-09 12 -

农场创业计划书模板VIP免费

2025-01-09 17

2025-01-09 17 -

奉节县特色农产品电子商务创业计划书模板VIP免费

2025-01-09 13

2025-01-09 13 -

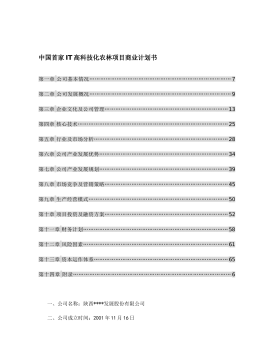

中国首家IT高科技化农林项目商业计划书VIP免费

2025-01-09 11

2025-01-09 11

作者:牛悦

分类:高等教育资料

价格:15积分

属性:79 页

大小:5.82MB

格式:PDF

时间:2025-01-09