药瓶自动装盒机的设计与开发

摘要自动装盒机械的结构与产品的包装方式、生产工艺有着直接的关系,它的设计研究涉及机械、材料、电子、控制及其它学科的知识理论。它的构成复杂,产品品种、形式和规格多种多样。计算机辅助设计应用于包装机械行业,方便产品开发人员设计、修改对应图纸,同时可根据相关图纸进行数据共享。而有限元分析软件应用于产品结构设计,与辅助设计软件相结合,实现产品设计与工程分析的相结合,结构优化逐步得到应用。本文着重阐述了药品包装领域的药瓶自动装盒机的设计流程,通过实际设计来验证设计流程的可行性。从项目总体方案设计、方案选择、具体部件系统设计到整个虚拟样机的建立,研制开发的药瓶自动装盒机结构合理、功能齐全、生产效率高、稳定...

相关推荐

-

THE COLOR FACTORY ——色彩心理康复体验中心设计VIP免费

2024-09-24 13

2024-09-24 13 -

中英大学生创业教育参与主体比较研究VIP免费

2024-09-30 58

2024-09-30 58 -

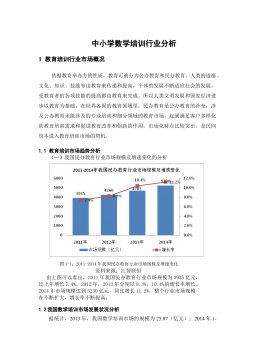

中小学数学培训行业分析VIP免费

2024-09-30 21

2024-09-30 21 -

英国大学生创业教育保障体系及其经验借鉴VIP免费

2024-09-30 67

2024-09-30 67 -

我国大学生创业教育的现状问题及对策研究VIP免费

2024-09-30 41

2024-09-30 41 -

浅谈大学生创业教育中加强思想政治工作的对策问题VIP免费

2024-09-30 23

2024-09-30 23 -

关于我国大学生创业教育目标定位的思考VIP免费

2024-09-30 71

2024-09-30 71 -

大学生创业教育引入SIYB项目的分析研究VIP免费

2024-09-30 57

2024-09-30 57 -

大学生创业教育对策研究VIP免费

2024-09-30 53

2024-09-30 53 -

大学生创业教育存在的问题及对策浅析VIP免费

2024-09-30 65

2024-09-30 65

相关内容

-

中英大学生创业教育参与主体比较研究

分类:高等教育资料

时间:2024-09-30

标签:无

格式:PDF

价格:12 积分

-

中小学数学培训行业分析

分类:高等教育资料

时间:2024-09-30

标签:无

格式:DOCX

价格:12 积分

-

英国大学生创业教育保障体系及其经验借鉴

分类:高等教育资料

时间:2024-09-30

标签:无

格式:PDF

价格:12 积分

-

大学生创业教育对策研究

分类:高等教育资料

时间:2024-09-30

标签:无

格式:PDF

价格:12 积分

-

浅析大学生创业教育内容体系和模式

分类:高等教育资料

时间:2024-09-30

标签:无

格式:PDF

价格:12 积分