气动电磁阀流量特性与节能关系研究

气动电磁阀流量特性与节能关系研究摘要节能的重要性近些年越来越受到广泛关注,因此能量利用率较低的气动系统节能研究意义愈加凸显,而作为气动系统重要组成部分的电磁阀也是节能研究的内容之一。本文针对压缩空气通过气动电磁阀的能量损失与流量特性参数临界压力比b的关系进行了理论分析和试验研究,然后通过仿真手段寻求提高b值达到节能效果的流道结构优化方案。首先引入压缩空气能量损失评价指标——火用,通过理论分析推导出单位质量流量压缩空气通过电磁阀的火用损计算公式,并讨论了火用损的影响因素。试验部分选用声速流导C值相同但b值不同的两个电磁阀作为被测对象,通过测量电磁阀上下游的压力值p2和p1来计算b值差异对压缩空气...

相关推荐

-

人教PEP英语-((开学摸底测试 综合提升卷)2023-2024学年五年级英语上册开学摸底考试卷(一)(人教PEP版)VIP免费

2024-09-30 8

2024-09-30 8 -

人教PEP英语-((开学摸底测试 重难点必刷卷)2023-2024学年四年级英语上册开学摸底考试卷(二)(人教PEP版)VIP免费

2024-09-30 9

2024-09-30 9 -

人教PEP英语-((开学摸底测试 重难点必刷卷)2023-2024学年五年级英语上册开学摸底考试卷(二)(人教PEP版)VIP免费

2024-09-30 7

2024-09-30 7 -

人教PEP英语-((开学摸底测试 综合提升卷)2023-2024学年四年级英语上册开学摸底考试卷(一)(人教PEP版)VIP免费

2024-09-30 7

2024-09-30 7 -

人教PEP英语-(2023-2024学年六年级英语上册开学摸底考试卷A卷(人教PEP版)VIP免费

2024-09-30 8

2024-09-30 8 -

人教PEP英语-(2023-2024学年六年级英语上册开学摸底考试卷B卷(人教PEP版)VIP免费

2024-09-30 8

2024-09-30 8 -

人教PEP英语-(开学摸底测试 易错题精选卷)2023-2024学年五年级英语上册开学摸底考试卷(三)(人教PEP版)VIP免费

2024-09-30 7

2024-09-30 7 -

外研版英语-(开学摸底测试 易错题精选卷)2023-2024学年六年级英语上册开学摸底考试卷(三)(外研版三起)VIP免费

2024-09-30 8

2024-09-30 8 -

外研版英语-(开学摸底测试 易错题精选卷)2023-2024学年五年级英语上册开学摸底考试卷(三)(外研版三起)VIP免费

2024-09-30 8

2024-09-30 8 -

外研版英语-(开学摸底测试 重难点必刷卷)2023-2024学年六年级英语上册开学摸底考试卷(二)(外研版三起)VIP免费

2024-09-30 8

2024-09-30 8

相关内容

-

2021-2022学年牛津上海版(试用本)二年级上册期末模拟测试卷英语试卷(解析版)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOC

价格:5 积分

-

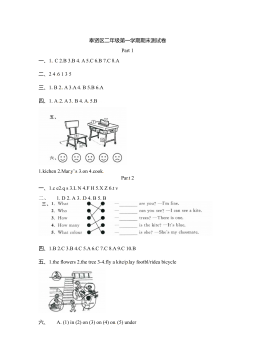

2019-2020学年2年级松江区英语上期末试卷答案

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

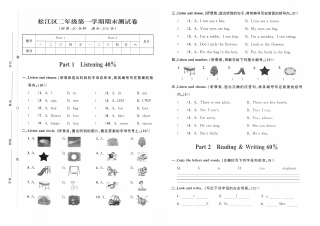

2019-2020学年2年级松江区英语上期末试卷

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:PDF

价格:5 积分

-

2019-2020学年2年级奉贤区英语上期末试卷答案

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOCX

价格:5 积分

-

2021-2022学年牛津上海版(试用本)二年级上册期中模拟测试英语试卷(原卷版)

分类:中小学教育资料

时间:2024-11-19

标签:无

格式:DOC

价格:5 积分